Habasit Italiana S.p.A.

Vittorio Veneto 31029 (TV)

Tel.: ++39(0)438.9113

Fax. ++39(0)438.200545

Hot Press PM-306/160

Author:

A.T. / KM

REGULATIONS AND GENERAL WARNING NOTES

Edition: 09/2005

Page

A-12

Replaces:

A.8

Qualification of personnel

Each task must be assigned to a person trained in the work to be carried out and trained in correct usage

as well as fully aware of any remaining risks and dangers in that work. Personnel must not carry out work

outside their area of competence, knowledge and responsibility.

T

ABLE

4

-

Q

UALIFICATIONS

FIRST LEVEL MACHINE CONTROL OPERATOR

Indicates non qualified personnel i.e. without specific competencies and able only to

carry out simple tasks, including in practice running the machine with the use of the

controls on the push-button panel and loading and unloading materials used during

production. Furthermore, this operator can work with the machine while the

machine's protective devices are enabled, to carry out simple, ordinary jobs for

adjusting, starting or re-starting production following enforced down-time.

MECHANICAL MAINTENANCE PERSON

A qualified technician able to run the machine under normal conditions, to intervene

on mechanical parts to make all adjustments as well as the necessary mechanical

maintenance and repair jobs, also with the protective devices disabled.

ELECTRICAL MAINTENANCE PERSON

A qualified technician able to run the machine under normal conditions, and also with

the protective devices disabled; s/he is entrusted with all electrical jobs involving

adjustment, maintenance and repairs. This operator is able to work while the interior

of the cabinets and the connector blocks are electrically live.

QUALIFIED TECHNICIAN

A person who is by training, experience, education and knowledge of accident

prevention regulations and procedures able to perceive and avoid possible dangers

and who is authorized by the plant's safety officer to carry out all necessary

mechanical and electrical intervention.

SPECIALIZED SUPERVISOR

An expert, specialized technician provided by the Manufacturer to carry out complex

operations in particular situations, installation, first start-up, instruction of the

Customer's personnel, as well as overhauls of and modifications to the machine.

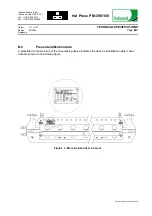

Hot-pressing device PM-306/160