ES0381 rev P 01/08

1

SL-20/30/40 Lathes

STEADY REST OPTION

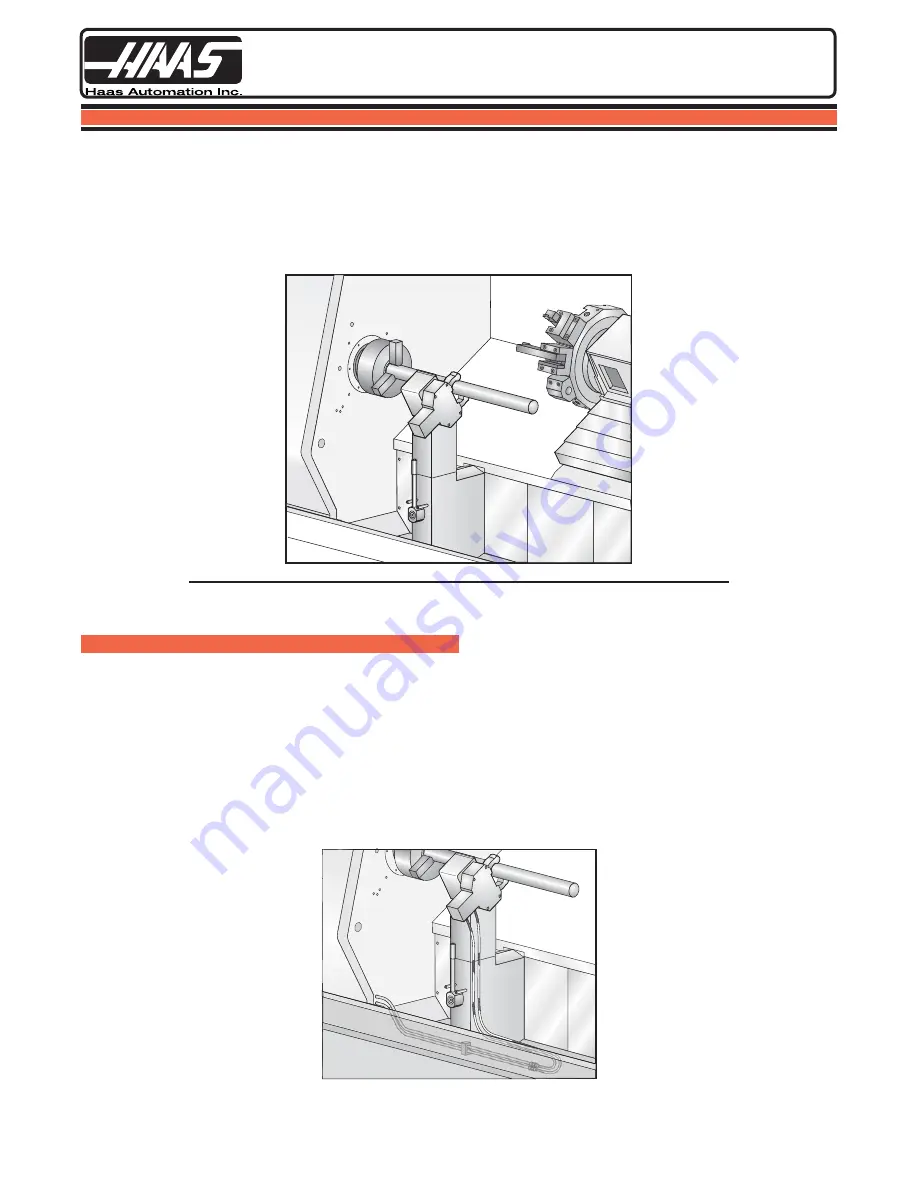

The steady rest platform provides for increased support of longer shaft turning and boring operations using

various automatic hydraulic aftermarket steady rests. The steady rest mounting platform is manually posi-

tioned along the Z-axis and is locked in place by a mechanical clamp. It can be used in conjunction with the

tailstock option.

Industry standard mounting holes to accept a variety of aftermarket steady rest grippers manufactured by

LMC, Forkhardt, SMW Systems, Rohm, and SMW Autoblock.

NOTE:

Some brands and/or models of steady rests may not fi t the Haas bolt pattern and

a special adaptor plate would need to be fabricated by the customer.

S

TEADY

R

EST

H

EAD

I

NSTALLATION

Install the steady rest on the platform. Do not tighten the mounting bolts as the head unit will need to be

aligned during the part setup. This is described in the following section.

Attach the existing hydraulic hoses, from the lathe, to the steady rest head. These are just inside of the lower

sheetmetal, above the chip tray. The fi ttings at the end of the hoses are female JIC-4. The hose to clamp

the steady rest is attached to the top tube and the unclamp hose is attached to the lower tube. If necessary,

secure the fl exible hoses so they do not come in contact with any chip removal system.

Position the steady rest along the Z-axis by pulling the clamp handle toward the spindle to release the clamp.

Push the steady rest to the desired location and reengage the clamp.