15

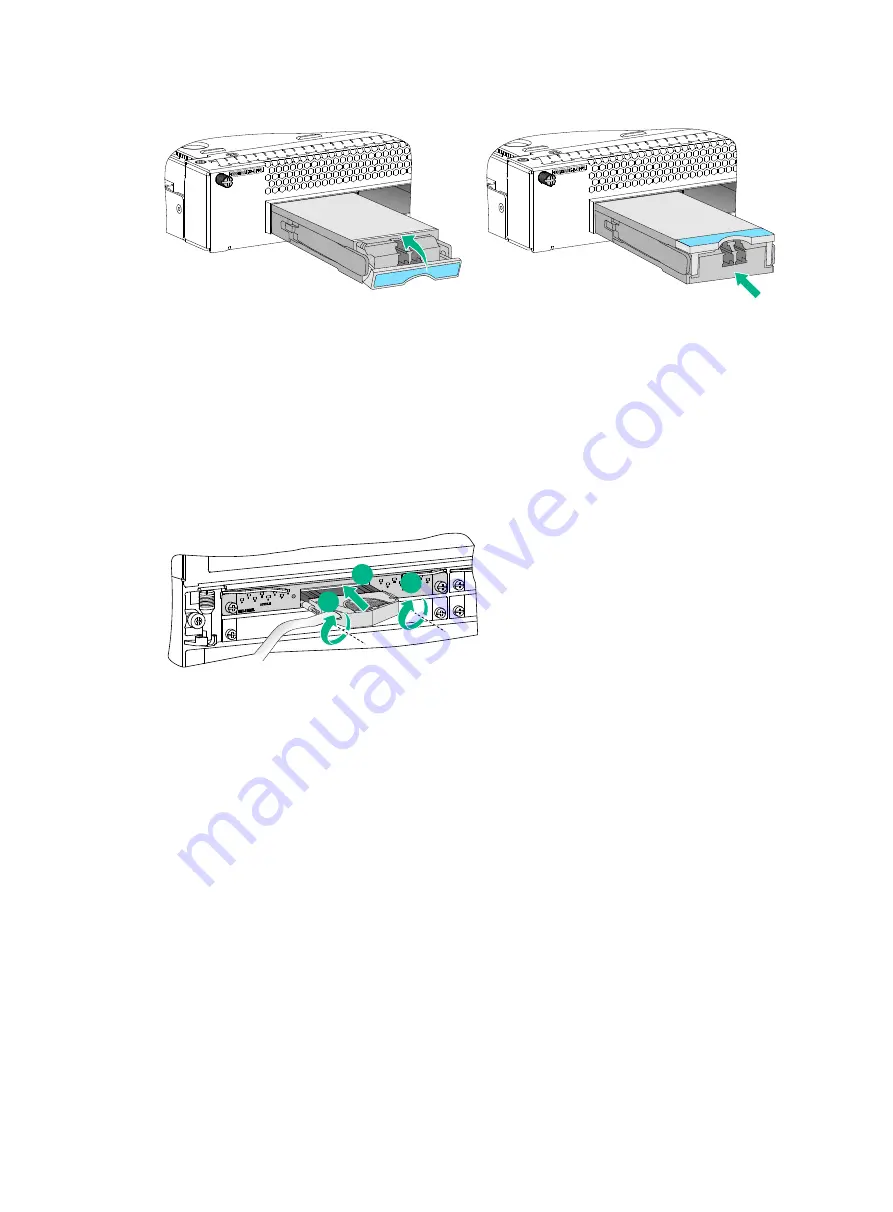

Figure 20 Installing a CFP2 transceiver module

Connecting an E1 cable

1.

Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

For more information, see "

."

2.

Connect the HD96 connector of the E1 cable to the interface on the subcard and use a

screwdriver to fasten the screws on the connector.

3.

Connect the other end of the E1 cable to the peer device.

Figure 21 Installing an E1 cable

Installing an SMB coaxial clock cable

1.

Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

For more information, see "

."

2.

Remove the dust plug from the target clock port.

3.

Insert the SMB connector of the SMB coaxial clock cable into the clock port.

4.

Connect the other end of the SMB coaxial clock cable to the peer network device.

1

2

2

Summary of Contents for CR16000-F

Page 40: ...9 Figure 11 Securing the power cord method one Figure 12 Securing the power cord method two...

Page 47: ...16 Figure 22 Installing an SMB coaxial clock cable...

Page 66: ...5 Figure 5 Removing a common card Figure 6 Removing a card with a locking clip 1 3 2...

Page 76: ...15 Figure 19 Replacing an SMB coaxial clock cable...

Page 89: ...12 Figure 14 Example of a device label...