A

B

A

B

A

B

A

B

A

B

15

©

Guldmann

GB/US

-02/2021 • # 550216_19

©

Guldmann GB/US

-02/2021 • # 550216_19

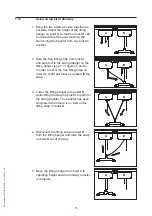

1 .13

Using swing kit in doorway

1.

Bring the two hoists as close together as

possible. Adjust the height of the lifting

hanger on hoist B so that the transfer can

be done without the user touching the

floor during the transfer from one hoist to

another.

2.

Take the free lifting strap from hoist A

and secure it to the swing adapter on the

lifting hanger

(see 1.10 figures 5 and 6).

In order to lower the free lifting strap on

hoist A a slight pull must be applied to the

strap.

3.

Lower the lifting hanger using hoist B

while lifting the strap on hoist A to perform

the swing transfer. The transfer has been

completed when there is no load on the

lifting strap on hoist B.

4.

Disconnect the lifting strap on hoist B

from the lifting hanger and raise the strap

on hoist B out of the way.

5.

Move the lifting hanger from hoist A to

operating height and the doorway transfer

is complete.