PERFORMANCE AND CONSUMPTION DATA

* This quick guide does not replace the IOM. Please refer to the IOM product detailed technical instructions

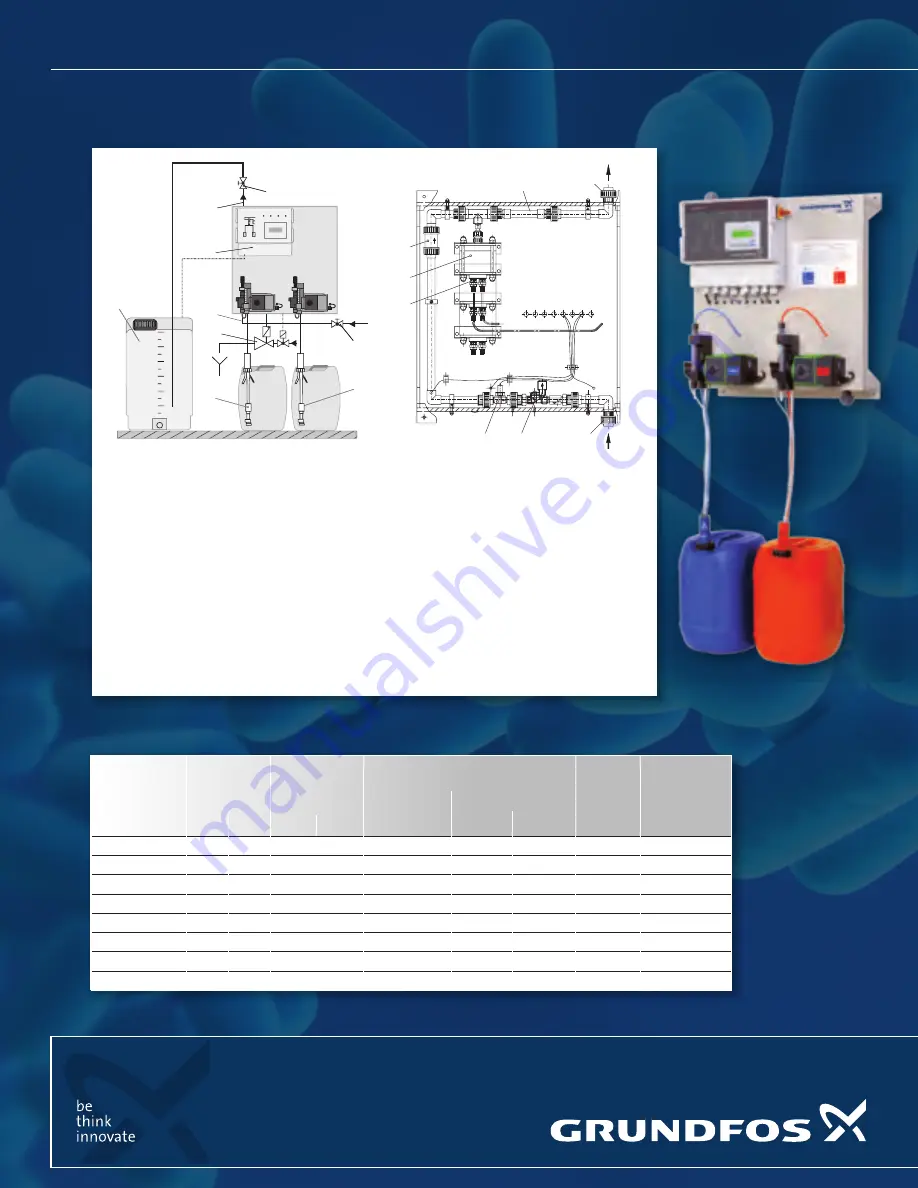

SYSTEM DESIGN

Oxiperm® 164 D Batch operation

1

Oxiperm® 164 D electronics

2

Connection for bypass water input

3

Connection for the ClO2 solution line

output to the injection unit

4

Suction line for the HCl dosing pump

5

Suction line for NaClO2 dosing pump

6

Shutt-off valve (by customer)

7

Shut-off valve (by customer)

8

Exhaust system for supporting rack (optional)

9

Dilution tank with level monitoring (optional)

for batch operation

10

Solenoid valve

11

Flow meter

12

Precursor check valves

13

Reaction chamber

14

Ball check valve

15

Back pressure valve

HCl

NaClO

2

ClO

2

9

3

6

1

8

5

4

7

2

P

A

P

A

14

13

12

11

10

2

3

15

ClO

2

preparation

capacity

p

max

[bar]

Consumption of

components

[l/h]

Consumption of bypass water [l/h]

(input pressure < p

max

)

Weight

Type

continuous

operation

batch operation *)

0.5 - 2 g/l

2 - 3.3 g/l

[kg]

[g/h]

50 Hz

60 Hz

HCl

NaClO

2

30

10

10

0.7

420

14

14 - 7.7

33

164-030D (DFI)

120

9

6

2.9

420

55

55 - 31

34

164-120D (DFI)

220

7

7

5.2

420

100

100 - 56

34

164-220D (DFI)

350

9

9

8.3

420

160

160 - 89

57

164-350D

700

9

9

16.5

900

320

320 - 179

62

164-700D

1000

9

9

24

900

450

450 - 258

66

164-1000D

1500

9

9

35

900

680

680 - 383

76

164-1500D

2000

9

6

48

900

900

900 - 517

82

164-2000D

grundfos

Oxiperm batch mOde

quick reference guide

L-DIS-SL-01.04-13.indd 1

4/11/2013 2:24:12 PM