English (GB)

13

7.2.4 Explanation to operating mode

Control enumeration for selection of the remote operating mode.

7.2.5 Setpoint in closed-loop control

Hydro MPC and Multi-E

The setpoint is written to module 2 bytes 4 and 5 Setpoint as a

percentage value scaled in 0.01 % of the sensor maximum value,

module 46 FeedbackSensorMax. The sensor minimum value is

always 0. The selected setpoint is reflected in module 41

UserSetpoint with the same scaling.

The actual setpoint, whether it has been set via Grundfos GO

Remote, the pump display, the pump buttons or the fieldbus, can

be read from module 20 ActualSetpoint. It is a percentage value

scaled in 0.01 % of module 46 FeedbackSensorMax.

Generally, the actual setpoint value represents head, pressure,

flow, temperature and so on depending on what the feedback

sensor has been set to measure. The unit of measure can be

read from module 44 FeedbackSensorUnit.

Unless a setpoint influencing function, like proportional influence,

is active, ActualSetpoint equals UserSetpoint.

It is possible to calculate back and forth between the setpoint in

percent and its scaled value:

X

act

[unit] =

X

set

[%]

×

FeedbackSensorMax

×

FeedbackSensorUnit

* Percentage of sensor maximum.

Fig. 17

Setpoint in closed-loop control for Hydro MPC and

Multi-E

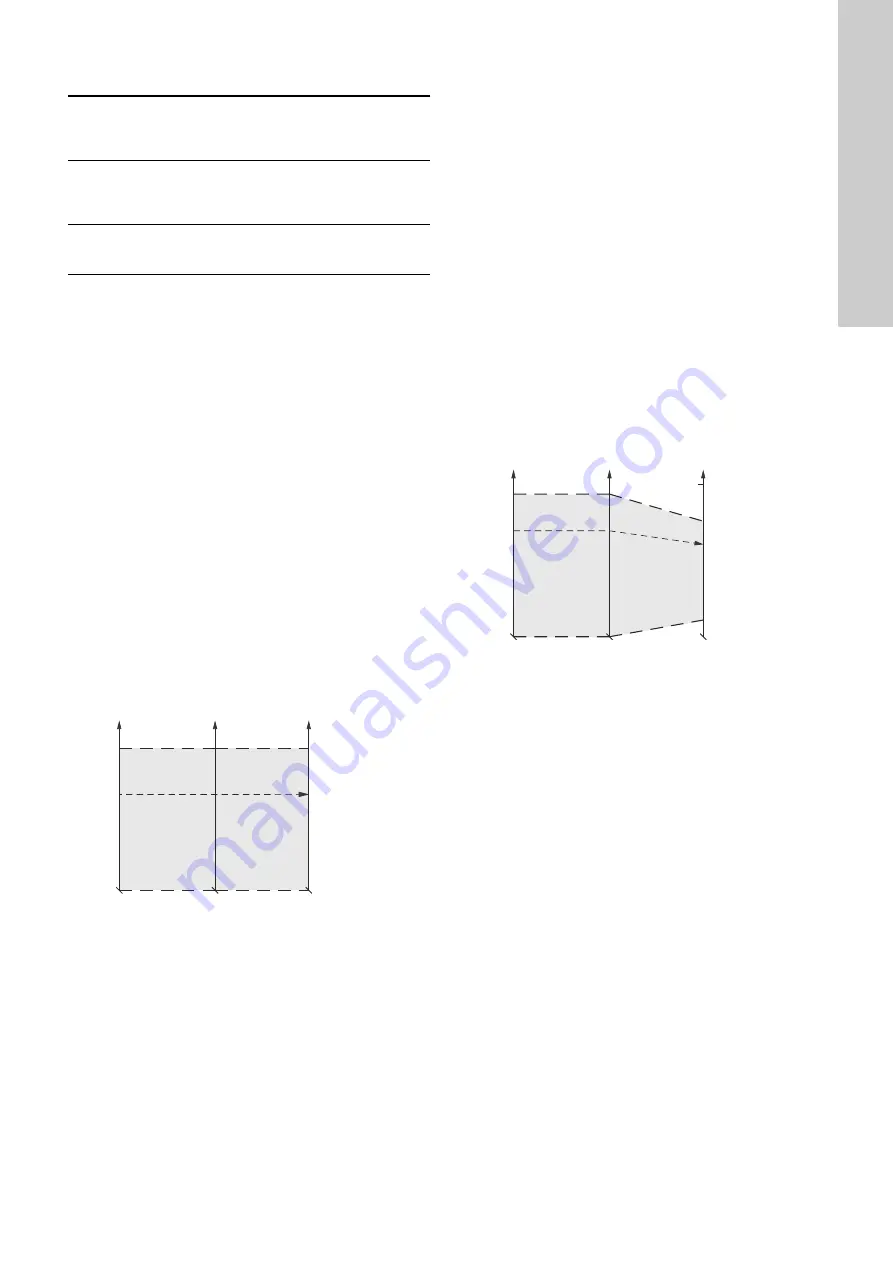

TPED and MAGNA3-D

The setpoint is written to module 2 bytes 4 and 5 Setpoint as a

percentage value scaled in 0.01 % of the setpoint range [r

min

;

r

max

]. The selected setpoint is reflected in module 41

UserSetpoint with the same scaling.

The actual setpoint, whether it has been set via Grundfos GO

Remote, the pump display, the pump buttons or the fieldbus, can

be read from module 20 Actua Setpoint. It is a percentage value

scaled in 0.01 % of module 46 FeedbackSensorMax.

Generally, the actual setpoint value represents head, pressure,

flow, temperature and so on depending on what the feedback

sensor has been set to measure. The unit of measure can be

read from module 44 FeedbackSensorUnit.

It is possible to calculate back and forth between ActualSetpoint

in percent and its scaled value:

X

act

[unit] =

X

act

[%]

×

FeedbackSensorMax

×

FeedbackSensorUnit

The setpoint range limits r

min

and r

max

cannot be read from the

fieldbus but can be found in the pump data sheet or they can be

seen in the Grundfos GO Remote "Setpoint" menu.

* Percentage of setpoint range.

** Percentage of sensor maximum.

Fig. 18

Setpoint in closed-loop control for TPED and

MAGNA3-D

0:

AutoControl

This is the normal mode. The booster system is controlled

according to the selected control mode and setpoint.

See section

7.2.3 Explanation to control mode

.

4:

OpenLoopMin

The booster system operates at a fixed minimum

performance.

Note:

Not supported by Hydro Multi-E.

6:

OpenLoopMax

The booster system operates at a fixed maximum

performance.

T

M

07

01

47

43

1

7

X

set

0 %

100 %

X

act

FeedbackSensor

Max (module 46)

Setpoint*

(ControlModule

byte 4 and 5)

UserSetpoint*

(module 41)

ActualSetpoint*

(module 20)

TM

07

01

48

43

17

X

act

FeedbackSensor

Max (module 46)

Setpoint*

(ControlModule

byte 4 and 5)

UserSetpoint*

(module 41)

ActualSetpoint**

(module 20)

r

min

r

max

100 %

X

set

0 %

100 %

Pumpland.ru

Summary of Contents for CIM 150 PROFIBUS DP

Page 34: ...34 Pumpland ru...