Model T32003 (Mfd. Since 02/20)

-19-

Loading Compound

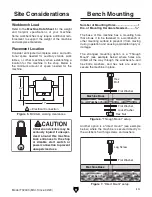

5. Apply buffing compound to rotating face of

wheel, as shown in

Figure 15. Only hold

compound to wheel for 2–5 seconds. The

polisher is now ready for buffing/polishing.

6. Turn machine OFF when operation is

complete.

Figure 15. Location where buffing compound

should contact wheel.

W

he

el

R

ota

tion

Right Front

Side View

Only Apply

Compound

Here

TOP

BOTTOM

FRONT

Select a buffing compound and buffing wheel that

is suitable for the workpiece and each sequence

of the buffing or polishing operation.

To load compound on wheels:

1. Select buffing wheel suitable for workpiece

(refer to

Selecting Buffing Wheels on Page

18). Follow directions on Page 18 to install

wheel.

2. Select buffing compound suitable to material

(refer to

Selecting Buffing Compounds and

Buffing Compound Sequence Key).

Note: Make sure buffing wheel is free of any

compound used in prior buffing operation.

Clean with a buffing wheel rake if necessary

(see

Cleaning on Page 22).

3. Put on safety glasses, face shield, and respi-

rator, then connect machine to power.

4. Stand to side of buffing wheel and turn

machine

ON. Allow wheel to reach full speed.

Selecting Buffing

Compounds

Most colors of abrasives have similar applica-

tions, but always check with the manufacturer of

your particular compound.

Grizzly offers the following compounds:

Red Rouge — Made for fine polishing on brass

and gold. Provides an excellent shine when used

with the loose muslin buffing wheel.

Green (Extra Fine) — Great for extra-fine pol-

ishing on most metals to bring out that mirror fin-

ish. Works best with loose muslin and spiral

sewn buffing wheels.

White — Great for ivory, plastic and resins when

used successively with the soft spiral sewn and

soft airway buffing wheels.

Black — Designed to be used with sisal and air-

way hard buffing wheels, this compound is per-

fect for the initial rough cut on stainless steel and

iron.

Tripoli — A true middle-of-the-road abrasive,

Tripoli provides an excellent medium cut for

brass, aluminum and zinc alloy.

Green (Fine) — Slightly more abrasive than the

extra-fine green, this green compound is great

for a medium-to-fine polish with most softer

metals.

Plastics

Soft

Metals

Thin

Plating

Gold

Silver

Chrome

& Nickel

Plate

Copper

Brass

Aluminum

Iron

Steel

Stainless

Steel

Compound

Type

Tripoli

Dark Rouge

White Rouge

Black Rouge

R F P R F P R F P R F P R F P

X

X

X

X

X

X

X

X

X

X X

X

Buffing Sequence: R = Rough F= Final Cut, Initial Polish P = Final Polish

Buffing Compound Sequence Key

Summary of Contents for T32003

Page 32: ......