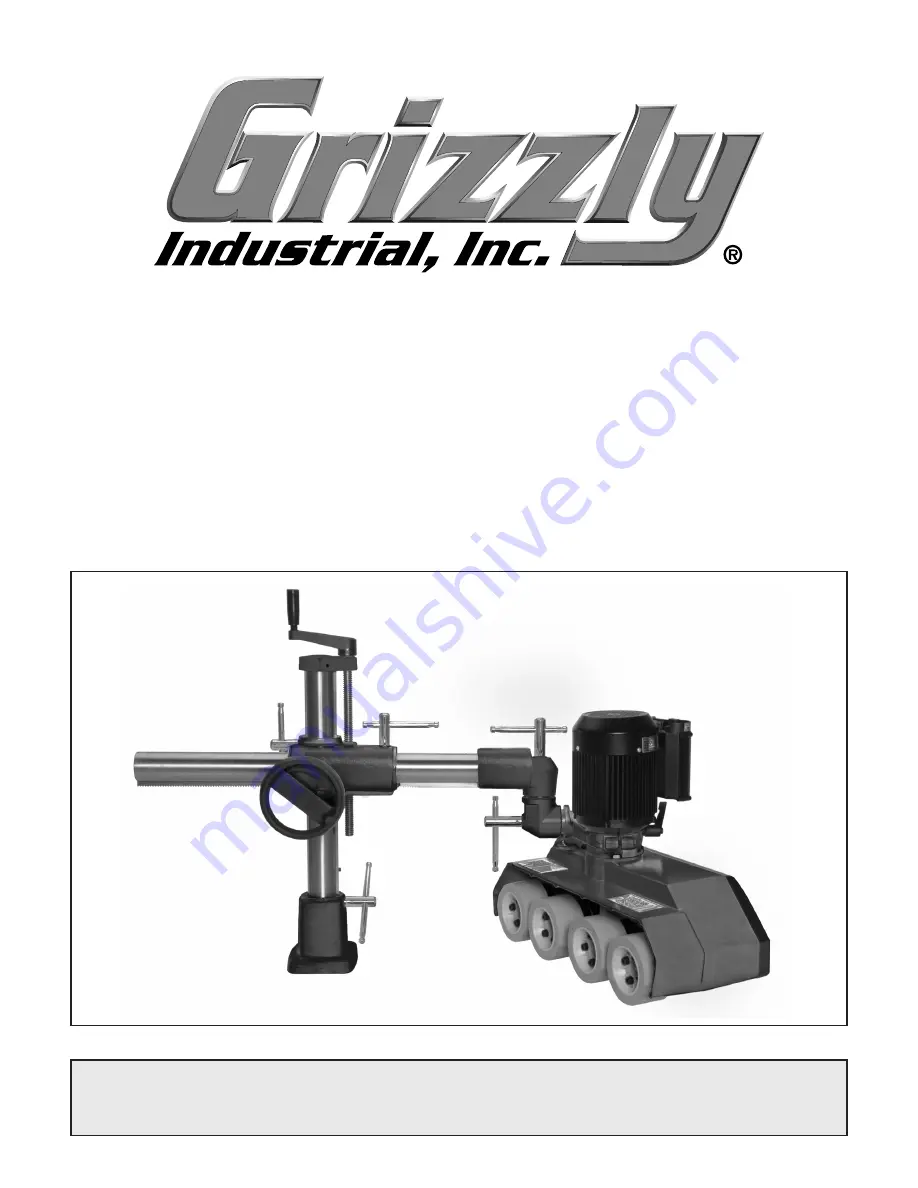

MODEL G1095/G1096

1-HP POWER FEEDER

with 4-ROLLER & 4-SPEED

OWNER'S MaNuaL

Copyright © MAy, 2008 By grizzly industriAl, inC.

WaRNiNG: NO PORtiON OF tHiS MaNuaL May bE REPRODucED iN aNy SHaPE

OR FORM WitHOut tHE WRittEN aPPROvaL OF GRizzLy iNDuStRiaL, iNc.

#Cr10667 printed in tAiWAn