If you are not experienced with this type

of machine, WE STRONGLY RECOMMEND

that you seek additional training outside of

this manual. Read books/magazines or get

formal training before beginning any proj-

ects. Regardless of the content in this sec-

tion, Grizzly Industrial will not be held liable

for accidents caused by lack of training.

DO NOT start machine until all preceding

setup instructions have been performed.

Operating an improperly set up machine

may result in malfunction or unexpect-

ed results that can lead to serious injury,

death, or machine/property damage.

To reduce your risk of

serious injury, read this

entire manual BEFORE

using machine.

The purpose of this overview is to provide the nov-

ice machine operator with a basic understanding

of how the machine is used during operation, so

the machine controls/components discussed later

in this manual are easier to understand.

Due to the generic nature of this overview, it is

not intended to be an instructional guide. To learn

more about specific operations, read this entire

manual, seek additional training from experienced

machine operators, and do additional research

outside of this manual by reading "how-to" books,

trade magazines, or websites.

-30-

Model G0911–G0914 (Mfd. Since 05/21)

To complete a typical operation, the operator

performs the following:

1. Creates artwork using desired design soft-

ware, prepares artwork for cutting/engraving

using RDWorks software, and exports .RD

file for upload (

Page 31).

2. Inspects auxiliary systems (water chiller, air

pump, and extraction fan) before every use.

3. Turns machine and auxiliary systems ON,

then verifies systems are operational.

4. Transfers design to machine and loads file for

cutting/engraving (

Page 35).

5. Selects and installs appropriate table for

operation.

6. Verifies workpiece is suitable for cutting/

engraving.

7. Places workpiece between table and laser

head assembly.

8. Sets laser focal length (Page 37).

9. Sets origin by pushing Origin button on con-

trol panel.

10. Verifies working envelope by performing

"Track" function (

Page 38).

11. Verifies total operation time by performing

"Work time" function (

Page 39).

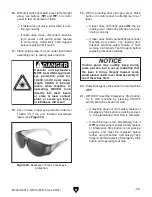

12. Puts on Class 4 laser eye protection and

wears it while operating machine.

13. Begins laser operations (Page 42).

14. Removes workpiece and scrap material from

cabinet once operations are completed.

15. Turns machine and auxiliary systems OFF.

16. Cleans and prepares machine for additional

operations.

SECTION 4: OPERATIONS

Operation Overview

Summary of Contents for G0911

Page 100: ......