-50-

Model G0899 (Mfd. Since 10/20)

SECTION 5: SHOP MADE SAFETY

ACCESSORIES

Easily made from scrap stock, featherboards

provide an added degree of protection against

kickback, especially when used together with

push sticks. They also maintain pressure on the

workpiece to keep it against the fence or table

while cutting, which makes the operation easier

and safer because the cut can be completed with-

out the operator’s hands getting near the blade.

The angled ends and flexibility of the fingers allow

the workpiece to move in only one direction.

Making a Featherboard

This sub-section covers the two basic types of

featherboards: 1) Those secured by clamps, or 2)

those secured with the miter slot.

Material Needed for Featherboard

Hardwood

3

⁄

4

" x 3" x 10" (Minimum)

Hardwood

3

⁄

4

" x 6" x 28" (Maximum) ..................1

Additional Material Needed for Mounting

Featherboard in Miter Slot

Hardwood

3

⁄

8

" x (Miter Slot Width) x 5"L ...........1

Wing Nut

1

/

4

"-20 ..................................................1

Flat Head Screw

1

⁄

4

"-20 x 2" ...............................1

Flat Washer

1

⁄

4

"-20..............................................1

To make a featherboard:

1. Cut a hardwood board approximately

3

⁄

4

" thick

to size. The length and width of the board

can vary according to your design. Most

featherboards are 10"–28" long and 3"–6"

wide. Make sure the wood grain runs paral-

lel with the length of the featherboard, so the

fingers you will create in

Step 3 will bend

without breaking.

2. Cut a 30º angle at one end of the board.

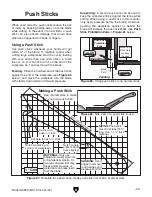

Featherboards

A

B

30°

2"-3"

1

⁄

16

"-

1

⁄

8

"

Kerf

1

⁄

16

"-

1

⁄

8

"

Kerf

2"-3"

10" (Minimum)

Initial Cut

Progressively

Longer Cuts

3

⁄

8

"

3

⁄

8

"

Figure 79. Patterns for featherboards (top view).

3. Make a series of end cuts with the grain

3

⁄

8

"–

1

⁄

4

" apart and 2"–3" long, as shown in

Figure 79 (A). Alternatively, start cuts at 2"-3"

deep, then make them progressively deeper,

as shown in

Figure 79 (B).

IMPORTANT: Cuts made across the grain result

in weak fingers that easily break when flexed.

When made correctly, the fingers should with-

stand flexing from moderate pressure. To test the

finger flexibility, push firmly on the ends with your

thumb. If the fingers do not flex, they are likely too

thick (the cuts are too far apart).

We recommend using a bandsaw for mak-

ing fingers in the next step because it tends

to be safer. A table saw can be used, but it

will over-cut the underside of the ends, pro-

duce a thicker kerf, and require you to stop

the blade half-way through the cut, which

can be dangerous.

Only Steps 1–3 are required to make a

clamp-mounted featherboard. Refer to Page

52 for instructions on clamping.

Summary of Contents for G0899

Page 92: ......