Model IGX Make-Up Air

27

®

5. Check Plenum Fan Radial Overlap, Offset,

Gap, and Wheel Alignment (if applicable)

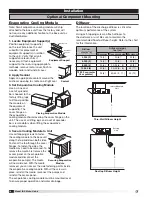

Backward-Curved Plenum Fan Radial Overlap

Proper wheel and inlet cone overlap is shown in the

chart. The overlap can be adjusted by loosening the

setscrews in the wheel and moving the wheel to the

correct position.

Backward-Curved Plenum Fan Radial Overlap

Overlap

Fan

Size

Overlap

in. (cm)

P114

0.14 (0.36)

P115

0.25 (0.64)

P120

0.20 (0.51)

P125

0.26 (0.66)

P128

0.28 (0.71)

Backward-Curved Plenum Fan Radial Offset

Radial offset is adjusted by loosening the wheel hub

from the shaft and moving the wheel to the desired

position along the shaft. The correct radial offset

between the inlet cone and wheel is shown in the chart.

There is a smooth feel to the profile when moving from

one component to the other.

Inlet

Cone

Wheel

Offset

Fan

Size

Offset

in. (cm)

P127

0.375 (0.95)

P222

0.250 (0.64)

P227

0.375 (0.95)

Backward-Curved Plenum Fan Radial Offset

Mixed Flow Plenum Fan Alignment

If necessary, adjust wheel position by loosening the

wheel hub from the motor shaft. Adjust wheel position

so that a straight edge held tight to the wheel cone just

touches the inlet cone.

Wheel Cone

Inlet Cone

Gap

Straight Edge

Mixed Flow Alignment

Supply Fan

Pre-Start Checks

Units with a direct drive backward-curved plenum

supply fan must always be supplied with a Variable

Frequency Drive (VFD) due to the direct drive

arrangement on the supply fan. Before proceeding

further, identify if this is a constant volume or Variable

Air Volume (VAV) unit. Reference the

Start-Up: Indirect

gas-Fired Heating, Optional Features, Variable Air

Volume

section in this Installation, Operation, and

Maintenance Manual for further information.

1. Check Electrical Connections

Tug test all internal electrical connections to ensure no

loose connections occurred during shipment.

2. Check Fasteners for Tightness

Check fasteners, set screws and locking collars on the

fan, bearings, drive, motor base, and accessories for

tightness.

3. Check Supply Fan Clearance

The rotation of the supply fan wheel is critical. It must be

free to rotate without striking or rubbing any stationary

objects.

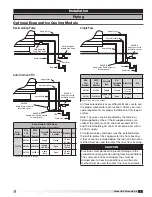

4. Check V-Belt Alignment (if applicable)

Check the V-belt drive

for proper alignment and

tension. Check the tension

by measuring the deflection

in the belt as shown.

Check the alignment by using a

straight edge across both sheaves.

Differences in sheave width must

be accounted for.

WARNING

Disconnect and lock-out all power and gas before

performing any maintenance or service to the unit.

Failure to do so could result in serious injury or death

and damage to equipment.

Check the housing, fan, and ductwork for any foreign

objects before running the fan.

TOOLS REQUIRED

• Voltage Meter (with wire probes)

• Amperage Meter

• Pressure Gauges

• Tachometer

• Thermometer

• U-tube manometer or equivalent

Drive Alignment

Belt Span

Deflection =

Belt Span

64

Belt Tension