Model IGX Make-Up Air

23

®

Installation

Piping

Guidelines for the installation of direct expansion (DX)

cooling coils have been provided to ensure proper

performance and longevity of the coils. These are

general guidelines that may have to be tailored to

meet the requirements of a specific installation.

Qualified personnel must perform the installation and

maintenance of any coil. Proper protective equipment is

recommended during the installation and maintenance

of the coil.

All field-brazing and welding must be performed using

high quality materials and an inert gas purge (such as

nitrogen) to reduce oxidation of the internal surface of

the coil.

All field-piping must be self-supporting and flexible

enough to allow for the thermal expansion of the coil

and piping.

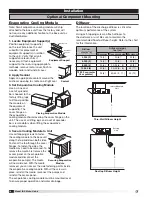

1. Locate the Distributor(s)

A field-provided opening must be

created for the liquid line(s). The

distributor(s) are located behind the

distributor access panel.

2. Verify Nozzle Placement

Inspect the refrigerant distributor

and verify that the nozzle is in place.

The nozzle is generally held in place

by a retaining ring or is an integral

part of the distributor itself.

The nozzle is not a metering

device. A thermostatic

expansion valve (TXV) must

be field-supplied.

3. Install Suction Line

Install suction line(s) from the compressor(s) to the

suction connection(s) which are stubbed through the

side of the cabinet.

4. Install the Liquid Line and Thermostatic

Expansion Valve (TXV) (by others)

Liquid line openings vary by coil size and circuiting and

are field-supplied. Follow the TXV recommendations

for installation to avoid damaging the valve. If the valve

is externally equalized, use a tubing cutter to cut off

the plugged end of the factory installed equalizer line.

Use a de-burring tool to remove any loose metal from

the equalizer line and attach it to the TXV. If the valve is

internally equalized, the factory-installed equalizer line

can be left as is. If a hot gas bypass kit was provided by

others, refer to the manufacturer’s instructions.

Distributor

Access Panel

Retainer

Ring

Nozzle

Distributor

General Installation

Expansion

Valve (by others)

Liquid Line

Thermal

Nozzle

Suction Header

Coil

Distributor

Equalizer Line

Suction Line

Remote Sensing Bulb

Straps

Suction Connection

5. Mount the TXV Sensing Bulb (by others)

Mount the TXV sensing bulb to the horizontal run of the

suction line at the TXV manufacturer’s recommended

position and insulate it.

6. Check System for Leaks

Pressurize the coil to 100 psig with dry nitrogen. Leave

the system pressurized for a minimum of 10 minutes.

If the system holds the pressure, the hook-up can be

considered leak free. If the pressure drops by 5 psig or

less, re-pressurize the system and wait another

10 minutes. If the pressure drops again, there is likely

one or more small leaks which must be located and

repaired. Pressure losses greater than 5 psig indicate a

large leak that must be isolated and repaired.

7. Evacuate and Charge the System

Use a vacuum pump to evacuate the system. Measure

the vacuum in the system using a micron gauge

located as far from the pump as possible. Evacuate the

system to 500 microns or less, and then close the valve

between the pump and the system. If the vacuum holds

to 500 microns or less for one minute, the system is

ready to be charged.

A steady rise in vacuum pressure indicates that moisture

is still present and that the system must be further

vacuumed until the moisture has been removed.

Failure to obtain a vacuum of 500 microns or less

indicates a great deal of moisture or a leak. Break the

vacuum with a charge of dry nitrogen and recheck for

leaks. If no leaks are found, continue vacuuming the coil

until the desired vacuum is reached.

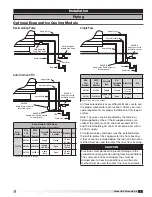

8. Install the Drain Line

Connect an unobstructed drain line to the drain pan. A

trap must be provided for proper unit drainage.

All traps must be

installed below

the roof line or be

otherwise protected

from freezing.

Optional Split Direct Expansion (DX) Coil

6 in./min. (0.254 cm/sec)

6 in./min. (0.254 cm/sec)

Drain

Trap