Model IGX Make-Up Air

15

®

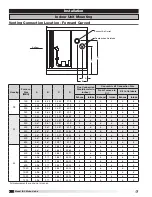

Slab

1. Pour Concrete Slab

Pour the concrete slab. Make

the slab one foot larger than

the unit on all sides. The slab

must be capable of supporting

the weight of the unit. Proper

subgrade preparation must be completed

under the slab. Allow the concrete slab to properly cure

before installing the unit.

2. Install Unit

Use a crane and a set of spreader

bars hooked to the factory lifting

lugs to lift and position the unit on

the concrete slab. The use of all

lifting lugs and a set of spreader

bars is mandatory when lifting the

unit. It is recommended that any

shipped loose modules be installed

after the base unit.

The shipped loose modules must be fastened together.

Fasten the cover seams and vertical panels on each

module using sheet metal screws. Using an appropriate

sealant, seal the seam(s) between each shipped loose

module and the weatherhood.

Some shipped loose modules will require field-provided

shims for proper alignment with the base unit.

If an optional evaporative cooling module is included,

reference

Installation, Optional Component Mounting,

Evaporative Cooling Module

section in this IOM for

more information.

Fasten the unit to the slab using appropriate methods.

The installer is responsible for determining appropriate

fastening methods to ensure compliance with all

applicable codes.

3. Attach Ductwork

Use an appropriate sealant

around the discharge opening

of the unit to create a weathertight seal.

Follow good duct practices for all ductwork. Install

ductwork in accordance with SMACNA and AMCA

guidelines, NFPA 96 and local codes. Reference

Installation, Duct Sizes

section in this Installation,

Operation, and Maintenance Manual for proper

duct sizes.

4. Install Stack (optional)

Clearance may require an exhaust stack. Install an

exhaust stack as needed to the exhaust connection on

the unit. Install a vent terminator on the exhaust pipe.

Exhaust transition and vent termination must be

purchased from the factory for proper operation.

Exhaust pipe is by others.

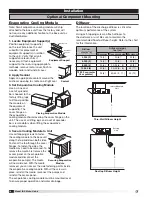

Rail

1. Install Rails

The rails must be located

around the perimeter

of the base unit on

all four sides. This is

required to ensure proper

unit support.

2. Install Unit

Use a crane and a set of

spreader bars hooked to

the factory lifting lugs to lift

and position the unit on the

field-supplied rail supports.

The use of all lifting lugs and

a set of spreader bars is

mandatory when lifting the

unit. It is recommended that

any shipped loose modules be

installed after the base unit.

The shipped loose modules must be fastened together.

Fasten the cover seams and vertical panels on each

module using the appropriate methods. Fasten the unit to

the rails using appropriate methods.

If an optional evaporative cooling module is included,

reference

Installation, Optional Component Mounting,

Evaporative Cooling Module

section in this IOM for

more information.

The installer is responsible for determining appropriate

fastening methods to ensure compliance with all

applicable codes.

3. Attach Ductwork

Use an appropriate sealant around the discharge opening

of the unit to create a weathertight seal.

Follow good duct practices for all ductwork. Install

ductwork in accordance with SMACNA and AMCA

guidelines, NFPA 96 and local codes. Reference

Installation, Duct Sizes

section in this Installation,

Operation, and Maintenance Manual for proper

duct sizes.

4. Install Stack (optional)

Clearance may require an exhaust stack. Install an

exhaust stack as needed to the exhaust connection on

the unit. Install a vent terminator on the exhaust pipe.

Exhaust transition and vent termination must be

purchased from the factory for proper operation.

Exhaust pipe is by others.

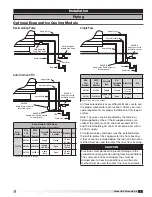

Installation

Outdoor Unit Mounting

Spreader Bar

Lifting

Lugs (4)