retract mechanism. Cut a clearance slot in rib W-3 for the LG

wire. Cut an opening in the bottom LE sheet and in rib W-2

FUSELAGE ASSEMBLY

for the wheel well.

3. lEnclose the wheel well by running vertical grain

1/16" balsa between the bottom and top sheeting; or you may

make the wheel well from an appropriately-sized styrofoam

cup.

of the spars) for your retract servo, and bend and fit a pushrod

to run between the servo and the retract mechanism. Run the

pushrod just under the top LE sheeting until it passes over the

wheel well, then make two 90-degree bends and connect it to

PREPARE FUSE SIDES

1. Lay one of the shaped 3/16" balsa fuselage sides in

place on the fuselage plan side view. Carefully position the

fuse side so the front edge lines up with the front ofF-1 on the

plan. Tape or pin the fuse side so it can't move. NOTE: The

fuse side may be a little longer at the rear than indicated by the

plan. This is as it should be.

the retract mechanism.

5. Temporarily mount yourretract servo and trial fit all

retract components. Test the operation of your retracts

making sure they operate freely and reliably. Also make sure

2. Carefully position the die-cut 3/16" balsa lower

front fuse side so the rear edge lines up with the front of the

wing saddle opening on the plan (the rear edge ofF-2A). You

may have to lightly sand the top edge of the die-cut 3/16"

balsa for a good fit against the bottom edge of the fuse side.

Edge glue the lower front fuse side to the fuse side. NOTE:

Use waxed paper under the balsa to avoid gluing to the plan.

they "lock" in both the up and down positions.

3. Carefully position the die-cut 3/16" balsa lower

rear fuse side so the vertical front edge lines up with the rear

of the wing saddle opening on the plan (the front edge of

F-4). Edge glue the lower rear fuse side to the fuse side.

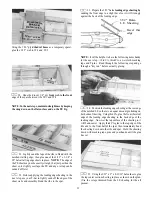

Photo shows finished wing with retract installed.

6. Blend the bottom sheeting as neatly as possible

around the retracts.

4. Trim and sand off the die-cut "bumps" from the

front and rear portion of the lower rear fuse side, blending

with the upper fuse side.

1. Use polyester resin or 30-minute epoxy thinned with

alcohol to fuelproof the entire retract well area.

5. Sand the fuse side smooth on both sides using a T-

bar and 100-grit sandpaper, then repeat the above steps to

make the other fuse side.

18