14

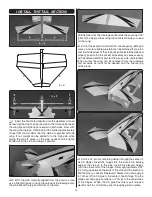

Press four 6-32 blind nuts into the holes as shown and apply

some glue around each nut to prevent them from coming loose.

❏

4. Glue the two rear pieces together. Assemble the rest

of the mount being sure to

thoroughly

glue all the joints

together. We suggest using thin CA on all the outside joints

and then running a bead of medium or thick CA along all the

inside joints.

❏

5. A short length of 1/8" [3.2mm] wood dowel is included.

Cut four 1/2" [13mm] pieces from the dowel. Drill 1/8" [3.2mm]

holes approximately 3/8" [9.5mm] deep into the center of each

forward tab. Glue a piece of dowel into each hole and sand

them fl ush with the sides of the motor mount.

❏

6. Attach the brushless motor mount to the fi rewall using

four 6-32 x 3/4" [19mm] machine screws, four #6 fl at washers,

four #6 lock washers, and thread locking compound.

❏

7. Install the aluminum ‘X’ mount and prop adapter onto

your brushless motor using the screws included with the

motor and thread locking compound. Attach the motor onto

the front of the brushless motor mount using four 6-32 x 5/8"

[15.9mm] machine screws, four #6 fl at washers, four #6 lock

washers, and thread locking compound.

❏

8. Locate the six plywood pieces that make up the ESC

tray. Glue them together as shown.

❏

9. It is recommended to make a 3" [76mm] battery lead

extension to make connecting your pack easier. In order to