❏ ❏

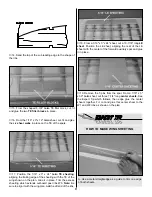

1. Place the stab over its location on the plan. Lightly

mark the hinge locations on the trailing edge with a ball

point pen. Mark the hinge locations on the elevator in the

same manner.

If you choose not to purchase a Slot Machine

™

you can

make the slots by following these instructions.

❏ ❏

2. Cut the hinge slots in the elevator and stabilizer using

a #11 blade. Begin by carefully cutting a very shallow slit at

the hinge location to accurately establish the hinge slot.

Make three or four more cuts, going a little deeper each

time. As you cut, slide the knife from side to side until the slot

has reached the proper depth and width for the hinge.

❏ ❏

3. Cut 3/4" x 1" hinges for the elevator from the

supplied 2" x 9" hinge material, then snip off the corners.

Temporarily join the elevator to the stab with the hinges,

adjusting any hinge slots if necessary so they all align. Do

not glue in the hinges until you are instructed to do so.

❏

4. Repeat steps 1 through 3 to hinge the rudder and fin.

❏

1. Shape the leading edge of the elevator and rudder to

a “V” as shown on the plan.

❏

2. Sand both sides of the elevator assembly smooth.

❏

3. Use a bar sander and 150-grit sandpaper to round the

tail surfaces, as shown on the plan.

Note: All of the wing ribs have been partially die-cut at the bottom

of the trailing edge. Use a hobby knife to complete the die-cut.

❏

1. Glue four die-cut 1/32" ply W2B’s to the four die-cut

1/16" balsa W2 ribs. Glue four more W2Bs to the other side

of the four W2 ribs. Note: Each of these rib assemblies is

now referred to as W2.

❏

2. Drill two 1/8" holes at the punch marks in each of the

four W2 ribs. Drill two 1/8" holes at the punch marks in each

of the two die-cut 1/8" balsa W3 ribs.

Build the Wing Center Section

BUILD THE WING

Finish the Tail Surfaces

1"

1"

3/4"

To cut the hinge slot, place the blades onto the wood

where you want the slot. Lightly press the teeth into the

wood. When you are satisfied with the location, press the

button on the handle and the blades will cut easily into the

balsa wood.

We have simplified the task of cutting hinge slots with the

introduction of the Great Planes Slot Machine

™

. This

simple electric tool cuts a perfect width slot for use with

CA hinges.

Hinge the Tail Surfaces

9

Summary of Contents for SlowPoke

Page 6: ...6 DIE CUT PATTERNS...

Page 32: ...TWO VIEW...