1 9

4 . To o l s S e t t i n g [ T O O L ]

What is Step Pass

A set of units by which cut data is processed is called Step Pass. If set, the cutting is performed by skipping blade

control for the data that is less than the specifi ed value. Set this setting when the space is extremely small in the

cut data, to reduce cut time while performing stable blade rotation control. The smaller the value is, the fi ner blade

control is performed and, therefore, the quality is improved but cut time becomes longer. Normally, set the value to

[0]. One unit is the distance that you set [Step Size] in [GP-GL] in the [Interface] screen (

¨

page 23).

What is Offset Angle

The plotter analyzes the cutting data to determine if blade angle control should be performed based on the

change amount of an angle. Angle control is performed when the change amount of an angle is equal to or more

than the value that you set in [Offset Angle]. If a small value is set, angle control is performed frequently for some

image shapes and, therefore, the quality is improved but cut time becomes longer. On the other hand, a large

offset angle value reduces the cut time but an image different from the intended one may be cut.

What is Data Sorting

This is a function to store plotting data in the buffer memory and arrange the process order so that more effi cient

plotting can be done.

By the Area sort, the process order is arranged so that the movement distance of the tool in the feed direction

becomes the shortest at tool up.

By the Tool sort, the process order is arranged so that plotting with Tool 1 is performed last if the data for Tool 1

and Tool 2 are mixed in the plotting data. Available only when 2 pen (Option) is selected.

If [Data Sort] is set to on, the time before the plotting starts becomes longer because data is temporarily

accumulated in the buffer memory.

Set the data sort in the controller to off when the data that has already been sorted with the application or driver

software is used for plotting.

10

Tool Select

Command

Specify whether to enable or disable tool replace commands ("J" in GP-

GL, "SP" in HP-GL), independently from the setting in [Condition Priority].

Enabled

Enables tool replace commands.

Disabled

Disables tool replace commands.

11

Initial Blade

Specify the position at which initial adjustment of the blade direction is

done.

¨

What is initial adjustment of the blade direction (page 20)

2mm Below

The initial adjustment of the blade direction is done

at 2 mm below the start point of the cutting.

Outside

The initial adjustment of the blade direction is done

outside of the cutting area.

12

Tool Up Move

Specify whether the plotter moves the tool each time it receives the

coordinates or directly moves the tool to the last coordinates when the

controller sends instructions in series to the plotter to raise and move the

tool.

Enabled

The tool moves along the coordinates received.

Disabled

The tool moves to the last coordinates.

13

Position

(Use Keyboard)

Click this key and then use the keyboard to move the tool to the position

at which the you want to cut the test pattern.

Up/down/left/right

Press one of the [

←↑↓→

] keys on the keyboard.

High-speed

movement

Press the [Ctrl] key and one of the [

←↑↓→

]

keys on

the keyboard at the same time.

Low-speed

movement

Press the [Shift] key and one of the [

←↑↓→

] keys

on the keyboard at the same time.

Skew

Press the up/down arrow key and the left/right

arrow key at the same time. For example, [

←

] and

[

↑

] or [

↓

] and [

→

].

14

OK

Saves the settings and closes the [Tools Setting] screen.

15

Cancel

Cancels the settings and closes the [Tools Setting] screen.

*1: Available only when you use a plotter with the 2 pen option.

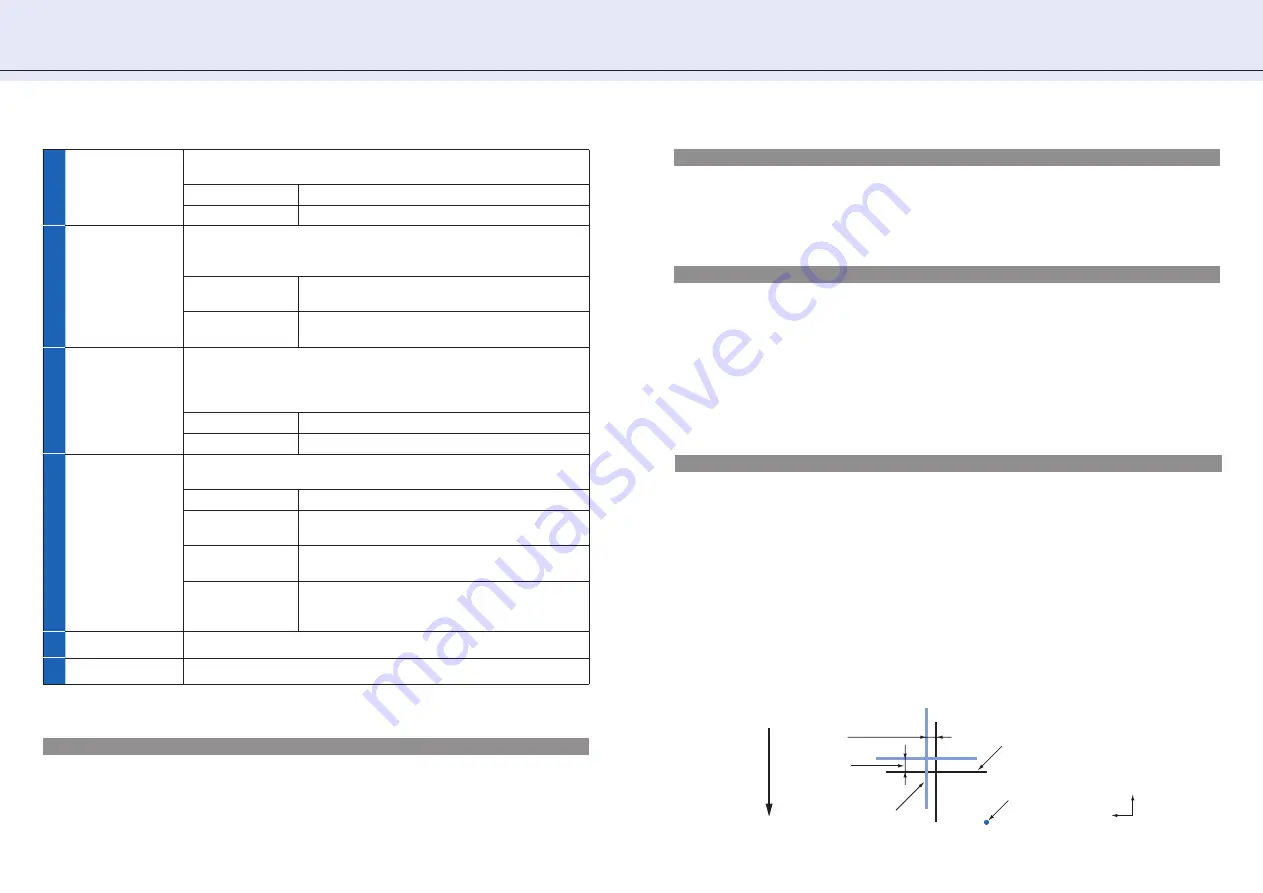

Tool 1-2 Offset ADJ./Tool 1-3 Offset ADJ.

Specify how much Tool 2 or Tool 3 is moved based on the Tool 1.

•Tool 1-2 Offset ADJ.

Adjust the positions of Tool 1 and Tool 2 in the plotter with 2 pen option. Use this setting when there is a difference

between drawings by the two tools. For adjustment values X and Y, see the fi gure below.

•Tool 1-3 Offset ADJ.

Adjust the positions of Tool 1 and Tool 3 Use this setting when there is a difference between drawings by the two

tools. For adjustment values X and Y, see the fi gure below.

1. Correctly set the Cutter plunger or 2 Plotter pens, and turn on the power source.

2. Make sure that the plotter is in ready status.

3. Open the [Tools Setting] screen of the controller.

4. Click the [Position (use Keyboard)], and then use the keyboard of PC to move the Tool carriage to the position at

which you want to cut the [+] (test pattern). (For both X and Y directions, move it to 50mm and over inside of the

plotting area.)

5. Click [Test Pattern] to cut the test pattern.

6. Measure the distance between 2 tools through the test pattern plotted.

Cross shape drawn with

the physical pen 1

The pen's starting

position

Feed dir

ection of media

Distance adjustment

value X

Distance

adjustment

value Y

Cross shape drawn with

Tool 2 or 3

X

Y