Gun

Gun

Gun Operation

Operation

Operation Troubleshooting

Troubleshooting

Troubleshooting

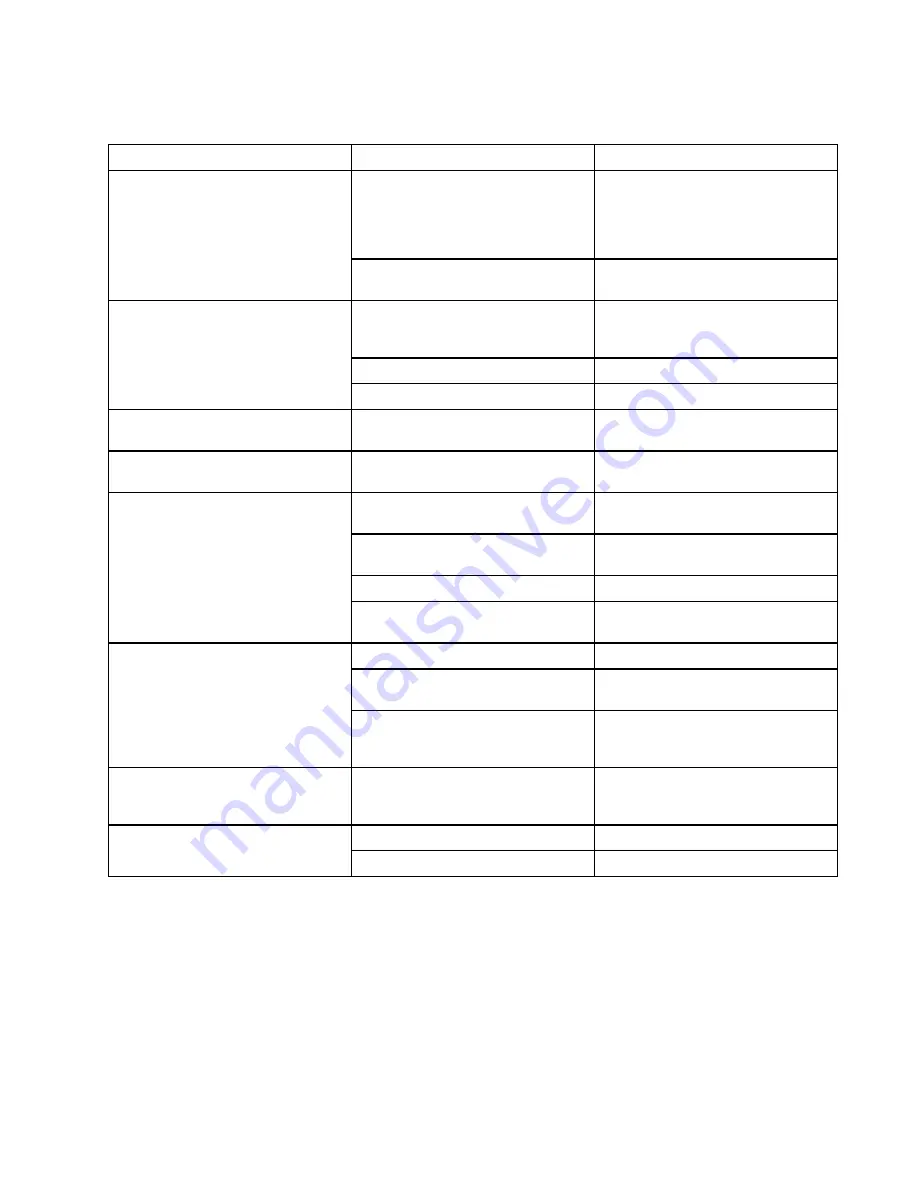

Problem

Problem

Problem

Cause

Cause

Cause

Solution

Solution

Solution

Atomizing air pressure too high.

Close restrictor valve part way, or

decrease air pressure as low as

possible; minimum 45 psi (0.32

MPa, 3.2 bar) needed at gun for

full voltage.

Excessive spray fog.

Fluid too thin, or fluid flow is too

low.

Increase viscosity or increase fluid

flow rate.

Atomizing air pressure too low.

Open atomizing air valve more or

increase gun air inlet pressure;

use lowest air pressure necessary.

Poorly mixed or filtered fluid.

Remix or refilter fluid.

“Orange Peel” finish.

Fluid too thick.

Reduce viscosity.

Fluid leaks from the fluid packing

area.

Worn packings or rod.

Replace packings. See

Air leaks from the front of the gun.

Air valve is not seating properly.

Replace air valve. See

.

Worn electrode.

Replace electrode. See

Electrode Replacement, page 61

Worn fluid nozzle seat.

Replace nozzle. See

.

Loose fluid nozzle.

Tighten.

Fluid leakage from the front of the

gun.

Damaged nozzle o-ring.

Replace o-ring. See

.

Low fluid supply.

Add fluid if necessary.

Dirty or clogged fluid nozzle.

Clean.

See

.

Gun does not spray.

Closed or damaged fluid

adjustment valve.

Open valve, or see

ES On-Off and Fluid Adjustment

Valve Repair, page 71

Dirty air cap.

Misaligned air cap and fluid nozzle.

Clean fluid buildup off air cap

and fluid nozzle seat. See

.

Poor grounding.

See

Excessive paint wrap back to

operator.

Incorrect distance from gun to part.

Should be 8–12 in. (200–300 mm).

3A2496H

55