14

306-863

Extension Kit 207–049

Converts Standard Gun 206–718 or 207–300 to a pole gun.

INSTALLATION

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 6.

1.

Relieve pressure. Disconnect the fluid hose.

2.

Remove the nuts (19) and gasket retainer (29) and

gasket (15) from the kit needle (20). Leave the

large gasket (28) on the needle.

3.

Install the new gasket (15) and gasket retainer (29)

in the gun outlet. Torque to 190–210 in–lb (23–24

N.m).

4.

Guide the new needle (20) into the gun body.

Screw the nuts (19) onto the needle.

5.

Slide the extension tube (30) over the needle and

tighten securely onto the gun.

6.

Remove the nozzle adapter (21) from the exten-

sion. Install the metallic gasket (15) in the seat

cavity of the extension (30). Screw the original gun

seat (21) into the extension. Torque to 190–210

in–lb (23–24 N.m).

7.

Install the gasket (5) and screw on the nozzle

adapter (31). Install the spring (7) on the rear of

the needle.

8.

Before completing the assembly, adjust the

needle. See page 6.

WARNING

Proper needle adjustment is essential to be sure

the safety latch makes the gun inoperative when

engaged. Improper adjustment may allow the gun

to be triggered, even with the safety latch engaged,

resulting in serious injury, including fluid injection

and splashing in the eyes or on the skin.

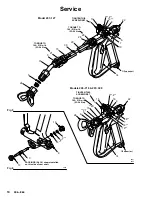

Dotted–line parts in this drawing indicate parts from

the original gun, Model 206–718 or 207–300.

Solid line parts are supplied in the Kit 207–049.

0966

30

20

28

29

15

19

7

6

22

15

21

5

31

5

24

TIP, order separately

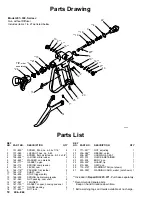

Model 207–049, Extension Kit

Includes items listed below.

REF

NO.

PART NO.

DESCRIPTION

QTY

5

166–969

WASHER, non–metallic

1

15

167–730

GASKET, copper, housing and seat 2

19

167–283

NUT, adjusting

2

20

207–134

NEEDLE, valve

1

28

167–284

GASKET, nylon

1

29

167–285

RETAINER, gasket

1

30

207–135

EXTENSION, gun; 37.5” (950 mm) lg1

31

207–136

ADAPTER, nozzle, 30

_

1

TORQUE TO

190–210 in–lb

(23–24 N.m)