5

307–452

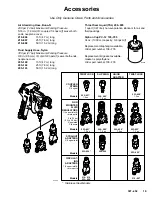

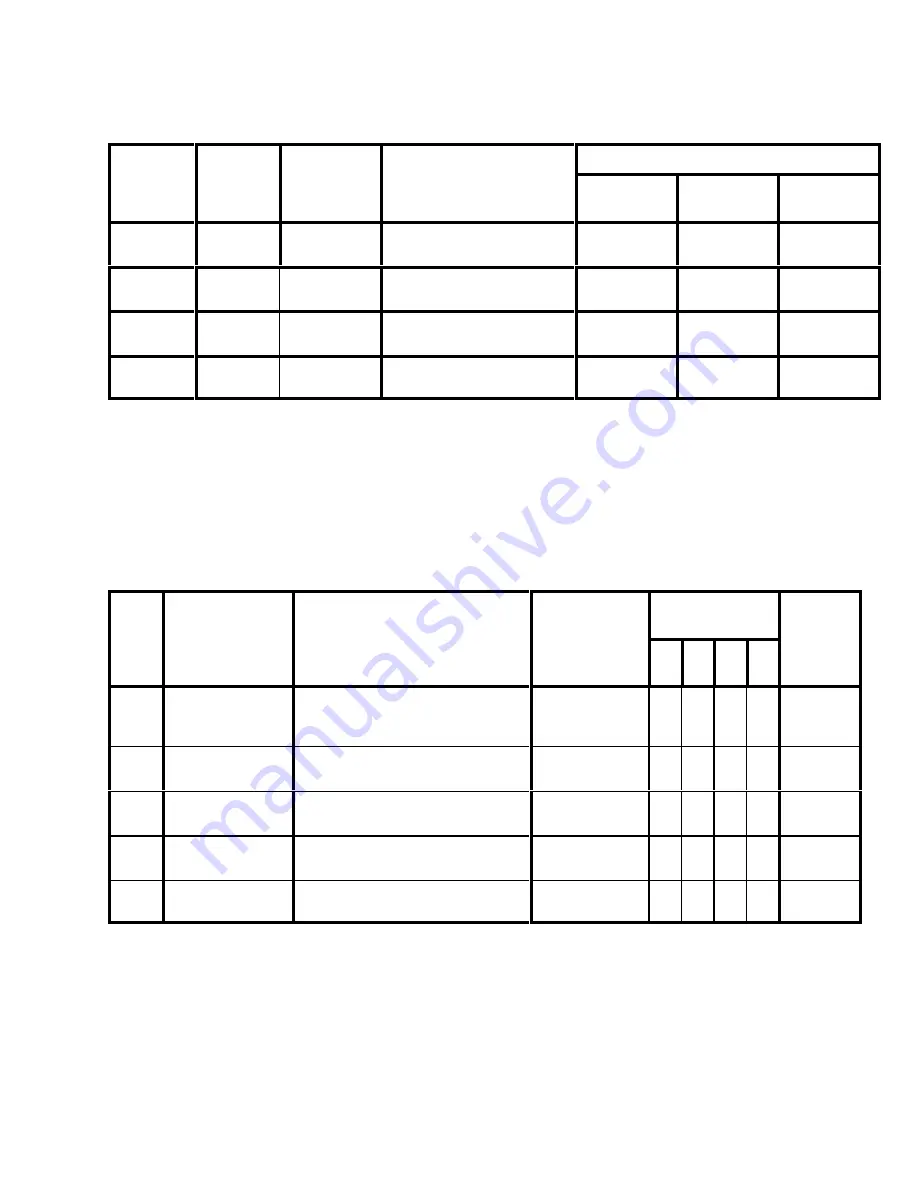

Ordering Charts

Chart 2: Fluid Nozzle/Needle Combinations*

Type

Flow Rate

Order Part Number

Type

Nozzle/

Needle

Orifice

Size

Flow Rate

fl oz/min

(liters/min)

Recommended Usage

(see TERMS above)

Kit

Nozzle Only

Needle Only

0N/0N

0.047”

(1.2 mm)

8–18

(0.24–0.54)

Light fluid

Pressure feed

106–766

106–750

106–758

{

11N/2N

0.055”

(1.4 mm)

4–10

(0.12–0.30)

Light fluid

Siphon feed

106–768

106–751

106–759

{

21N/2N

0.070”

(1.8 mm)

8–12

(0.24–0.36)

Medium fluid

Siphon feed

106–769

106–752

106–760

3N/3N

0.098”

(2.5 mm)

12–18

(0.36–0.54)

Heavy fluid

Siphon feed

106–770

106–753

106–761

* Needles and fluid nozzles are manufactured in matched, lapped sets and should be ordered as a kit to ensure per-

fect seating of the needle in the fluid nozzle.

{

Optional Plastic Tipped Needle, Part No. 108–704, can

be used with 0.047 in. (1.2 mm) and 0.055 in.

(1.4 mm) orifice size. Typical use is for extremely light viscosity fluids, such as stains and dyes.

NOTE: See page 17 for Fluid Flow Charts.

Chart 3: Air Caps Available

Pattern Length

Consumption

cfm at psi

Recommended

Nozzle

Order

Type

Pattern Length

at 10 in.

(254 mm)

Pattern Shape

Recommended Usage

cfm at psi

(m

#

/min

at bar)

0

11

21

3

Order

Part

Number

0

13–16”

(330–400 mm)

Long taper. Medium to high pro-

duction. Lacquers, acrylics,

epoxies.

15 at 50

(0.42 at 3.5)

X

106–700

03

9–13”

(230–330 mm)

Medium taper. Medium to high

production. Lacquers, acrylics.

16 at 50

(0.44 at 3.5)

X

106–706

11

8–10”

(200–250 mm)

Blunt end. Low to medium pro-

duction. Lacquers, enamels.

12 at 50

(0.34 at 3.5)

X

106–702

2

9–11”

(230–280 mm)

Blunt end. Medium production.

Lacquers, enamels.

11 at 50

(0.31 at 3.5)

X

106–703

3

11–13”

(280–330 mm)

Tapered. Medium to high produc-

tion. Heavy fluids.

12 at 50

(0.34 at 3.5)

X

106–705

NOTE: See page 16 for Air Flow Charts.