Operation

313347C

3

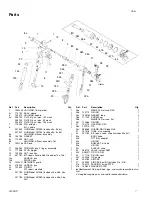

Tip and Guard on Gun

AA30 Gun with RAC Tip (257096)

1.

Relieve pressure, page 2.

2.

Insert seat housing (27)

into guard (29).

3.

Insert SwitchTip (28).

4.

Insert seal (27b) over

seat (27a) and insert in

seat housing (27). Use black seal for water-based

materials and orange for solvent and oil-based

materials.

5.

Install guard (6) over end of gun. Hand tighten firmly

to ensure a good seal.

6.

Replace seat (33a) and/or retighten guard nut if you

notice fluid leaking from front of gun.

AA30 Gun with Flat Tip (257380)

1.

Relieve pressure, page 2.

2.

Insert spray tip into flat tip air

cap assembly. Insert spray tip

locating tab (A) into air cap

locating slot (B).

3.

Install guard over end of gun.

Hand tighten firmly to ensure a

good seal.

Operation

Note: The following instructions are for guns used with

Graco FinishPro Sprayers. See the sprayer instruction

manual 313316. If you are using a different sprayer, see

your equipment instruction manual.

Setup

1.

Prime sprayer. See manual 313316.

2.

Slide air on/off valve on (up).

3.

Turn air adjustment valve off at

gun.

4.

Increase fluid pressure to

eliminate tails.

5.

Decrease fluid pressure until

just before tails start to

appear.

6.

Increase air pressure with air

adjustment valve to eliminate

tails.

7.

Slide air on/off valve off (down)

when finished spraying to save

proper air pressure setting.

Spray

1.

Unlock trigger lock.

2.

Be sure the arrow shaped tip (B) faces forward

(spray) (257096).

3.

Hold gun perpendicular and approximately 12 in.

(304 mm) from surface. Move gun first, then pull gun

trigger (D) to spray a test pattern.

4.

Do not spray in an arc. This causes an uneven fluid

coat. Spray in a path parallel to the surface, with a

50% overlap, to obtain an even fluid coat.

NOTICE

If air cap is not fully installed on gun, fluid pressure

can force paint into air line and damage sprayer.

27a

29

28

27

27b

ti8249a

A

B

ti13263a

ti12855a

ti13321a

ti13279a

ti13280a

ti13281a

WRONG

RIGHT