8

306715

Operation

Settings and Adjustments

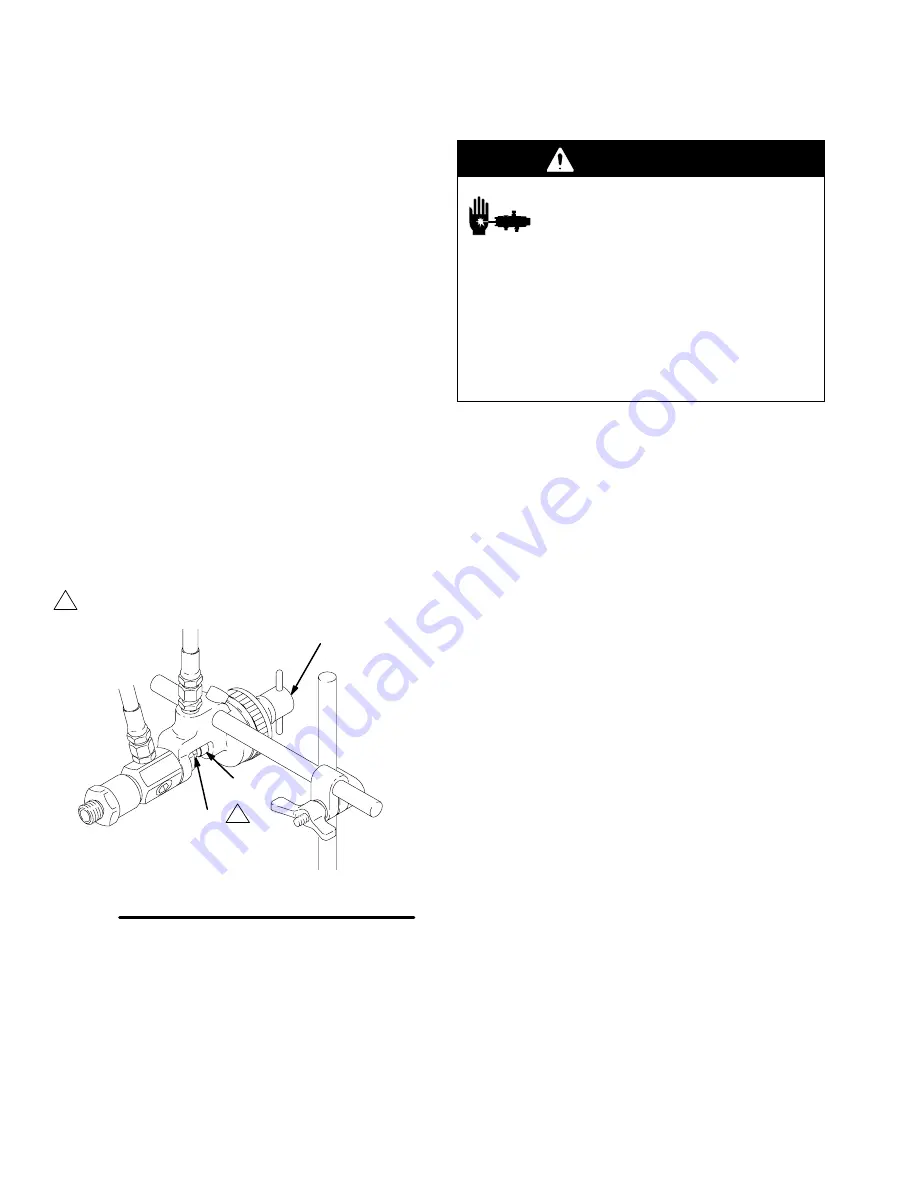

Before each day’s operation, lubricate the exposed

portion of the needle (22) and the piston (16) with a

lubricant compatible with the fluid being dispensed.

After lubrication, cover the exposed portions of the

needle and piston with a piece of plastic to prevent

fluid buildup on these parts. Any buildup could damage

the valve packing (9 or 20). See Fig. 3.

Set the actuating air to at least 50 psi (345 kPa, 3.4

bar) and start the pump. Adjust the pump speed and

pressure to obtain the desired flow rate. Always use

the lowest pump speed necessary to get the results

you want.

To decrease needle travel, turn the adjusting screw

(12) clockwise; to increase, turn counterclockwise. If

the valve leaks from the outlet after it is closed, turn

the adjusting screw clockwise until the valve stops

leaking.

In a circulating system, adjust the back pressure valve

to provide constant system back pressure for all dis-

pensing valves while maintaining the proper pressure

for fluid circulation. See the

Typical Installation

on

page 6.

Fig. 2

06482

16

22

Model 207440 Shown

1

1

Oil Daily

12

Pressure Relief Procedure

WARNING

INJECTION HAZARD

Fluid under high pressure can be in-

jected through the skin and cause

serious injury. To reduce the risk of an

injury from injection, splashing fluid, or moving

parts, follow the

Pressure Relief Procedure

whenever you:

D

are instructed to relieve the pressure,

D

stop dispensing,

D

check or service any of the system equipment,

D

or install or clean the nozzle.

1.

Shut off the power to the pump.

2.

Close the bleed-type master air valve (required

with air powered pumps).

3.

Actuate the dispensing valve to relieve pressure.

4.

Open the pump drain valve (required in your

system) to help relieve fluid pressure in the dis-

placement pump. Actuating the dispensing valve to

relieve pressure may not be sufficient. Have a

container ready to catch the drainage.

5.

Leave the drain valve(s) open until you are ready

to dispense again.

If you suspect that the dispensing valve or hose is

completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the hose end coupling and relieve pressure

gradually, then loosen completely. Now clear the valve

or hose.

Summary of Contents for 205435

Page 14: ...14 306715 Notes ...