Identification Systems

English, Revision 03, Date: 07.02.2012

4

1

Identification Systems

To ensure that the operating procedure is working properly, the data transmission be-

tween different objects (die carrier, tools, vehicles etc.) and the control system is de-

cisive. Mobile objects have to be identified and positioned fast and safely.

Thus identification systems provide a safe and economical solution, which can be in-

stalled easily. Using these systems it is possible to operate and control the process

flow.

Such a system is suitable for nearly all sectors in which production and transportation

processes have to be automated. For the realization of these automations, data has to

be recorded, collected and processed on the route of transport, at their final destina-

tion, at the premises and at the manufacturing site.

1.1

Application Examples for the Automation

Automation can be realized within the following sectors:

-

Storage

-

Position fixing of vehicles and containers

-

Production lines

-

Control of material flow

-

Identification of containers

-

Control of loading and unloading processes

-

Positioning of vehicles in industrial engineering

-

Distance control of track guided vehicles

-

Position fixing for public transport

Special advantages of the inductive identification system are a positioning accurate to

a millimeter, identification within a far range and an insensitiveness to contamination.

1.2

System Components

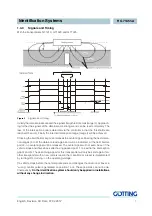

In order to create a whole positioning und identification system, transonders are need-

ed. The antenna HG 71451-A fits the following types:

Transponder HG 71325 (free codable) / HG 71370 (switch transponder)

Frequency

Antenna

Transponder

125 kHz

71451YA

71325ZA (other types on demand)

409 kHz

71451ZA

71325YA, 71370-A (switch transponder)

Table 1

Available antennas and transponders