SCHEDULED MAINTENANCE

13

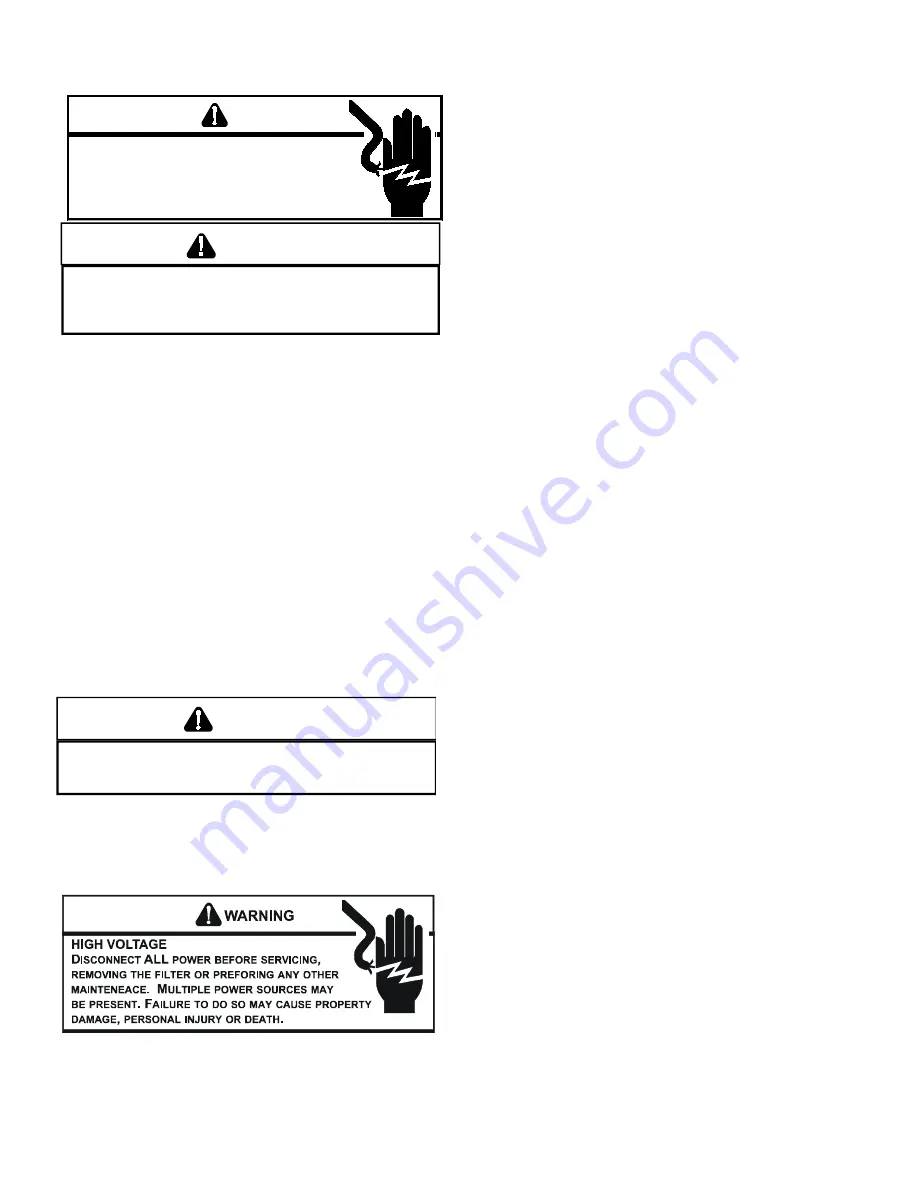

WARNING

H

I

GH

V

OLTAG

E

D

IS

CONN

E

CT

ALL

PO

WER

B

E

FO

RE

SERVI

C

I

NG O

R

I

N

S

TALL

I

NG TH

IS

U

N

I

T.

M

U

LT

I

PL

E

PO

WER

S

O

UR

C

ES

M

AY

B

E

P

RESE

NT.

F

A

I

L

URE

TO DO

S

O

M

AY CA

USE

P

R

OP

ER

TY

DA

M

AG

E

, P

ERS

ONAL

I

N

JUR

Y O

R

D

E

ATH.

I

F YO

U

MUS

T HANDL

E

TH

E

I

TN

I

TO

R

, HANDL

E

WI

TH CA

RE

.

T

O

U

CH

I

NG

TH

E

I

GN

I

TO

R

BODY

WI

TH BA

RE

F

I

NG

ERS

,

R

O

U

GH HANDL

I

NG, O

R

VI

B

R

AT

I

ON CO

U

LD

RESU

LT

I

N

E

A

R

LY

I

GN

I

TO

R

FA

I

L

URE

.

O

NLY A

QU

AL

I

F

IE

D

SERVI

C

ER

S

HO

U

LD

EVER

HANDL

E

TH

E

I

GN

I

TO

R

.

CAUTION

ANNUAL INSPECTION

The furnace should be inspected by a qualified installer, or

service agency at least once per year. This check should be

performed at the beginning of the heating season. This will

ensure that all furnace components are in proper working

order and that the heating system functions appropriately. Pay

particular attention to the following items. Repair or service

as necessary.

•

Flue pipe system. Check for blockage and/or leakage.

Check the outside termination and the connections at

and internal to the furnace.

•

Heat exchanger. Check for corrosion and/or buildup

within the heat exchanger passageways.

•

Burners. Check for proper ignition and flame sense.

•

Wiring. Verify that electrical connections are tight and

free from corrossion.

•

Filters.

AIR FILTER

N

EVER

OP

ER

AT

E

F

UR

NAC

E

WI

HTO

U

T A F

I

LT

ER

I

N

S

TALL

E

D A

S

D

US

T

AND L

I

NT

WI

LL B

UI

LD

U

P ON

I

NT

ER

NAL PA

R

T

S

RESU

LT

I

NG

I

N LO

SS

OF

E

FF

I

C

IE

NCY,

EQUI

P

ME

NT DA

M

A

M

G

E

, AND PO

SSI

BL

E

F

IRE

.

WARNING

Filters must be used with this furnace. Filters do not ship

with these furnaces but must be provided by the installer for

proper furnace operation.

Dirty filters are the most common cause of inadequate heating

or cooling performance.

Maintenance

Improper filter maintenance is the most common cause of

inadequate heating or cooling performance. Filters should

be cleaned (permanent) or replaced (disposable) every two

months or as required.

Horizontal Unit Filter Removal

Filters in horizontal installations are located in the central

return register.

INDUCED DRAFT AND CIRCULATION BLOWERS

The bearings in the induced draft blower and circulator blower

motors are permanently lubricated by the manufacturer. No

further lubrication is required. Check motor windings for

accumulation of dust which may cause overheating. Clean

as necessary.

FLAME SENSOR (QUALIFIED SERVICER ONLY)

Under some conditions, the fuel or air supply can create a

nearly invisible coating on the flame sensor. This coating acts

as an insulator, causing a drop in the flame sensing signal. If

this occurs, a qualified servicer must carefully clean the flame

sensor with steel wool. After cleaning, the flame sensor output

should be as listed on the specification sheet.

The following is a must for every service technician and

service shop.

1. Dial type thermometers or thermocouple meter (option-

al) - to measure dry bulb temperature.

2. Amprobe - to measure amperage and voltage.

3. Volt-Ohm Meter - testing continuity, capacitors, and

motor windings.

4. Inclined Manometer - to measure static pressure, pres-

sure drop across coils, filters, and draft.

5. Water Manometer (12”) - to test gas inlet and manifold

pressure.

Other recording type instruments can be essential in solving

abnormal problems, however, in many instances they may

be rented from local sources.

Proper equipment promotes faster, more efficient service and

accurate repairs resulting in fewer call backs.

HEATING PERFORMANCE TEST

Before attempting to diagnose an operating fault code, run

a Heating Performance Test to determine if the heating

system is performing within 5% of the BTU input found on

the rating plate of the unit being tested. To conduct a heating

performance test, the BTU input to the unit must be calculated

(see Clocking a Gas Meter). Before clocking a gas meter,

contact your local utility to provide the caloric value (BTU

content) of the natural gas in the area.

It is also important to confirm the airflow (CFM) is within the

temperature rise range (see Airflow Data in spec sheet) and

external static pressure range (approximately 0.5” water

column). How-to instructions can be found in the service

manual under Checking External Static Pressure and

Checking Temperature Rise.

Summary of Contents for AMES960403BU AA

Page 25: ...TROUBLESHOOTING 25...

Page 26: ...TROUBLESHOOTING 26...