8

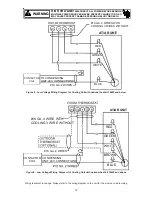

3” FLAT INSULATION

RETAINER

(BOTH SIDES)

Figure 4

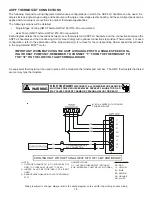

To complete the conversion, slide the evaporator coil into

the chassis and attach the three (3) access panels.

(Figure

5).

WRAPPER

INSULATION

JACKET

ZEE COIL

SUPPORT

WRAPPER

STIFFENER

DRAIN PAN

INSULATION KIT

BLOWER

ASSEMBLY

Figure 5

NOTE:

When converted to downflow position, the coil may

protrude above the cabinet on some models.

Horizontal Conversion

Dedicated Downflow models are not suitable for horizontal

application and must not be used for this type of installation.

The only field modification required for conversion to “Hori-

zontal Right-Hand” is the removal of the plastic knockouts in

the horizontal panel drain connections. To prevent the hori-

zontal drain pan from sweating in high humidity applications,

it is recommended that a DPIH insulation accessory kit be

used. NOTE: The DPIH insulation kit is not supplied with this

product and should be purchased separately. See

Table 8

for the correct DPIH kit.

ARUF, ATUF

or ARPF Model

Insulation Kit

1729 / 1824

DPIH18-32

3030 / 1931 / 3636

DPIH36-42

3642 / 3743 / 4860 / 4961

DPH48-61

Table 8

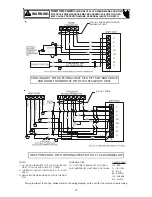

The following describes converting to “Horizontal Left-Hand”.

Conversion to downflow MUST be performed in an area that

allows access to all sides prior to placing the air handler in its

final location (

See Figure 6

).

PRIMARY

DRAIN

SECONDARY

DRAIN

DPIH KIT

Figure 6

1. Remove the (3) air handler access panels.

2. Remove the “J” shaped bracket that retains the evapo-

rator coil.

3. Remove the flowrator from the lower left side access

panel and slide out the evaporator coil and horizontal

drain pan.

4. Remove the gasket from the horizontal pan drain con-

nections.

5. Remove the oval shaped plastic plug from the left side

access panel. Remove the oval shaped rubber gasket

seal from the lower right side access panel.

6. The drain connections for the horizontal pan are sealed

with a thin coating of plastic. Carefully knock out this

plastic seal with a screwdriver and hammer.

Note: The

upper drain will become the secondary drain which

is mandatory in many municipalities .

7. Install the plastic plug removed in step 5 to the right

side lower access panel and the oval shaped rubber

gasket to the lower left access panel.

8. Reinstall the evaporator coil with the horizontal panel

on the left side. Note: Push the assembly completely to

the rear to ensure the engagement of the upflow pan

with the rear channel bracket.

9. Install the “J” bracket (removed in step 2) to support the

upflow pan to the tie channel.

10. Attach all panels and the metering device.

Condensate Removal

The coil drain pan has a primary and an optional secondary

drain with 3/4" NPT female connections. The connectors re-

quired can be 3/4" NPT male either PVC, CPVC or metal

pipe and should be hand tightened to a torque of approxi-

mately 37 in-lbs. to prevent damage to the drain pan connec-

tion. An insertion depth between .355 to .485 inches (3-5

turns) should be expected at this torque. Use the female (3/4

fpt) threaded fitting that protrudes outside of the enclosure

for external connections.

1. Ensure drain pan hole is NOT obstructed.

2. To prevent potential sweating and dripping on to finished

space, it may be necessary to insulate the condensate