25

Problem

Probable cause

Solution

The compressor does not

connect.

Power plug disconnected of

the outlet.

General key disconnected.

Missing power in the net.

Overload protector disarmed

(thermal relay).

Connect power plug in outlet.

Connect the general.

Wait normalization of the

net.

Rearm the protector as ins-

truction (pag.16).

IMPORTANT:

Before making rearming ve-

rify the possible faults that

caused it’s activation.

The compressor does not

connect and emits a not

normal noise.

Capacitor damaged.

Overload protector damaged.

Make the substitution of the

capacitor.

Make the substitution of the

overload protector.

The compressor does not

connect.

Feeding of electrical voltage

smaller.

Connect the compressor to

the correct net.

Wait for the net normali-

zation.

The compressor does not

reach maximum pressure,

smaller efficiency, it works for

a short period of time.

Damaged pressostat.

Air reservoir is with excess

of condensate water.

Air input filter with excess of

residues.

Motor head with damaged

gasket.

Make the substitution of pres-

sostat.

Drain the reservatory water.

Clean the air filter(s) or if ne

-

cessary make its substitution.

Make the motor substitution.

Note: the motor head should

be sent to the factory.

The compressor motor

doesn’t disconnect when

reaching the maximum

pressure and the safety valve

is activated.

Damaged pressostat.

Make the substitution of the

pressostat.

UNFORESEEN EVENTS – SOLUTION OF PROBLEMS

Disconnect the compressor and unload the air of the reservoir before making any

maintenance operation.

Summary of Contents for BioQualyAir 40L

Page 1: ......

Page 9: ...9 TECHNICAL SPECIFICATIONS Dimensions mm BioQualyAir 65L BioQualyAir 40L ...

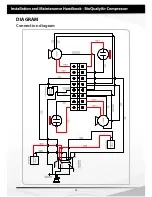

Page 24: ...24 DIAGRAM Connection diagram ...

Page 28: ......