3B3-6 POWER STEERING

— Sealing and bearing surfaces of the pitman

shaft (

221

) for roughness, nicks, or other dam

age. Replace the pitman shaft assembly if nec

essary.

— Pitman shaft (221) for excessive wear or scor

ing. C heck the se ctor gear teeth fo r w ear.

Replace the pitman shaft assembly if neces

sary.

— Adjuster screw (222) threads for wear. The

adjuster screw must be free to turn with no end

play.

2. Rack piston.

— Worm (248) and rack piston (214) grooves and

all balls (213) for scoring. BOTH M UST BE

REPLACED as a matched assembly.

— Seal (216) and ring (217) for wear.

— Ball return guide halves (212) for cracks and

damaged.

— Bearing (247) and races (246) for scoring and

excessive wear.

— Rack piston (214) teeth and external ground

surfaces for scoring or excessive wear. If either

condition exists, replace the rack piston (214)

and worm (248).

3. Adjuster plug.

— Spacer (235) for wear or cracks.

— Races (236, 238) for wear or scoring.

— Adjuster plug (240) threads for wear.

— Bearing (237) for wear or scoring.

— Needle bearing (241) for wear, pitting or scor

ing. Replace if necessary.

4. Valve and stub shaft.

— Seals (231) and rings (232).

— Shaft pin for wear or cracks. If excessively worn

or broken, replace the com plete valve and shaft

assembly.

— Ground surface of the stub shaft (251). If a cro

cus cloth ca nn ot clean the nicks or burrs,

replace the entire valve assembly.

— Outside diam eter of the valve spool and inside

diam eter of the valve body (250). If a crocus

cloth cannot clean the nicks or burrs, replace

the entire shaft and valve assembly.

— The small notch in the skirt of the valve for wear.

If worn replace the com plete valve assembly.

— Valve spool inside the valve body (250). The

valve spool, when lubricated with steering fluid,

must rotate freely w ithout binding. If binding

occurs, replace the com plete valve and shaft

assembly.

ASSEMBLY

■►4* install or Connect (Figures 1 ,4 , and 10 through 14)

Tools Required

J 4245 Snap Ring Pliers

J 6217 Valve C onnector

J 21552 Ball Retainer

J 22407 Bearing Installer

J 8092 Bearing Driver

J 7079 Bearing Remover and Installer

J 8524-1 Driver

J 7624 Bearing Preload Spanner W rench

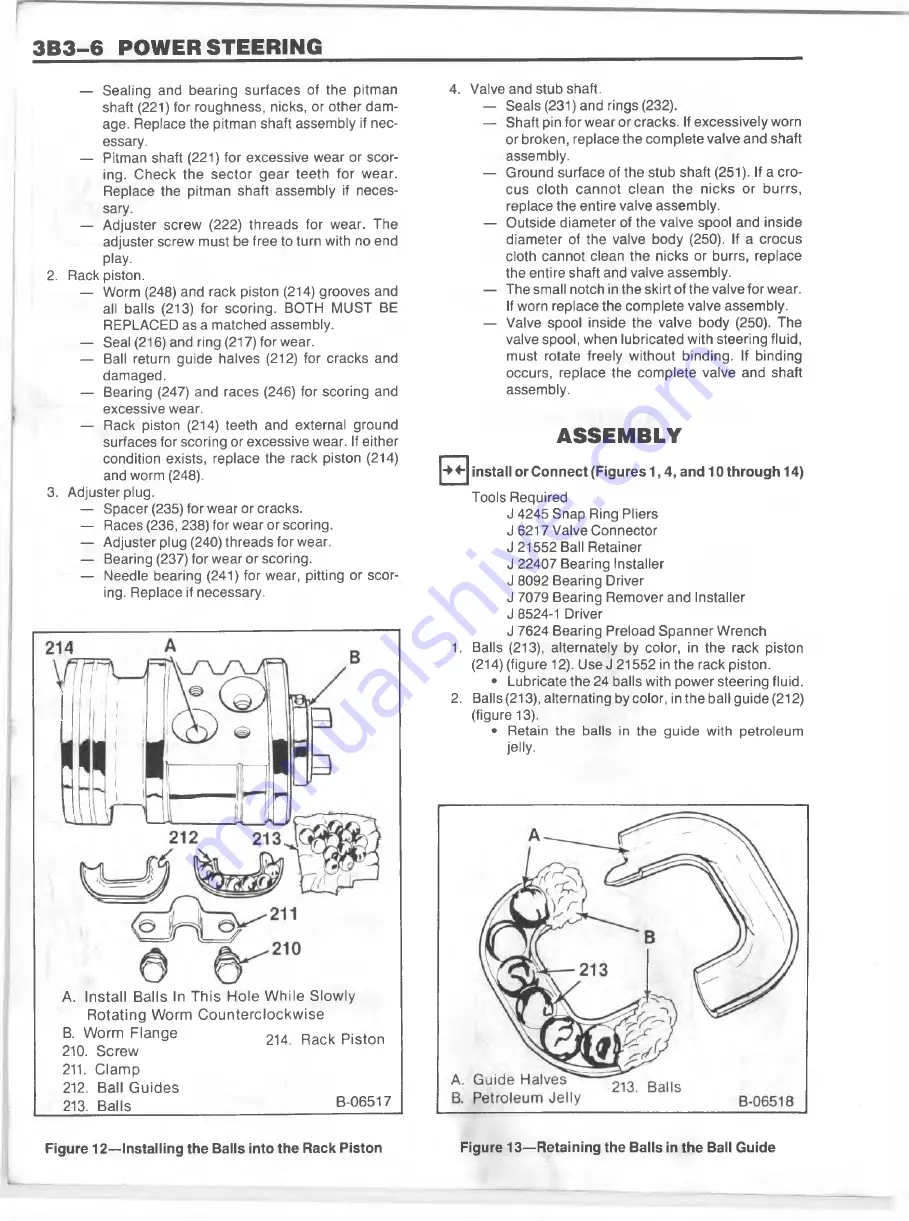

1

. Balls (213), alternately by color, in the rack piston

(214) (figure

1

2). Use J 21552 in the rack piston.

• Lubricate the 24 balls with power steering fluid.

2. Balls (213), alternating by color, in the ball guide (212)

(figure 13).

• Retain the balls in the guide with petroleum

jelly.

A. In s ta ll B a lls In T h is H o le W h ile S lo w ly

R o ta tin g W o rm C o u n te rc lo c k w is e

B. W orm F la n g e

2 U

R ack p js to n

210. S cre w

211. C la m p

212. Ball G u id e s

213. B a lls

B-06517

F ig u re 1 2 — Installing th e Balls into th e R ack P iston

Figure 1 3 — R etain in g th e B alls in th e Ball G uide

Summary of Contents for 1989 Light Duty Truck

Page 1: ...vr V Light Duty Truck Unit Repair Manual...

Page 2: ......

Page 11: ...GENERAL INFORMATION OA 5 Figure 8 RV Models...

Page 13: ...GENERAL INFORMATION OA 7 Figure 11 ST Models...

Page 18: ......

Page 44: ......

Page 76: ...1B3 18 R 4 AIR CONDITIONING COMPRESSOR N...

Page 114: ......

Page 162: ......

Page 176: ...4B3 14 91 2 INCH RING GEAR...

Page 192: ...4B5 4 DANA REAR AXLES Figure 4 Spreading the Differential Case Figure 7 Removing the Ring Gear...

Page 218: ......

Page 220: ...4B6 2 12 INCH RING GEAR ROCKWELL F 04734 Figure 1 Rear Axle Components...

Page 229: ...12 INCH RING GEAR ROCKWELL 4B6 11 SPECIAL TOOLS Special Tools...

Page 230: ...4B6 12 12 INCH RING...

Page 240: ...4B7 10 LOCKING DIFFERENTIALS SPECIAL TOOLS Special Tools...

Page 260: ...4C2 6 93 4 INCH RING GEAR FRONT AXLE Figure 16 Removing the Pinion Inner Bearing...

Page 273: ...T TRUCK FRONT AXLE 4C3 3 F 05785 Figure 1 Axle Components...

Page 291: ...K TRUCK FRONT AXLE 4C4 3 Figure 1 Front Axle Com ponents K 15 25 Models...

Page 293: ...K TRUCK FRONT AXLE 4C4 5 Figure 3 Front Axle Com ponents K35 Models...

Page 318: ...C4 30 K TRUCK FBOHT AXLE...

Page 334: ......

Page 361: ...2 5 LITER L4 ENGINE 6A1 5 Figure 3 Cylinder Head Manifolds and Components...

Page 363: ...2 5 LITER L4 ENGINE 6A1 7 F 05715 Figure 5 Block and Components...

Page 395: ...2 8 LITER V 6 6A2 3 Figure 1 Engine Lubrication Diagram...

Page 396: ...6A2 4 2 8 LITER V 6 Figure 2 Engine Lubrication Diagram...

Page 424: ...6A2 32 2 8 LITER V 6...

Page 427: ...I 4 3 LITER V 6 6A3 3 Figure 1 Engine Lubrication Diagram B 07857...

Page 451: ...4 3 LITER V 6 6A3 27 SPECIFICATIONS ENGINE SPECIFICATIONS F 6344...

Page 457: ...4 8 LITER L6 6A4 3 Figure 2 Lubrication Diagram Front View...

Page 460: ...6A4 6 4 8 LITER L6 C 1 107 112 fK 108 3 109 165 129 B 05056 Figure 5 Block and Components...

Page 490: ...Ml...

Page 493: ...V8 ENGINE 6A5 3 Figure 1 Lubrication Diagram 5 0L and 5 7L Engines...

Page 494: ...6A5 4 V8 ENGINE Figure 2 Lubrication Diagram 5 0L and 5 7L Engines...

Page 530: ...6A5 40 V8 ENGINE Figure 81 Exhaust Manifold 7 4L Engines Figure 82 Water Pumps and Components...

Page 571: ...6 2 LITER DIESEL 6A7 35 Figure 58 Vacuum Pump Installed...

Page 576: ......

Page 582: ...6C1 6 MODEL 1MEF CARBURETOR Figure 9 Monojet Model 1MEF...

Page 604: ...6C2 6 MODEL M4MEF CARBURETOR Figure 9 Model M4MEF...

Page 640: ...6C4 8 MODEL 700 THROTTLE BODY...

Page 652: ...nmm...

Page 672: ......

Page 693: ...DISTRIBUTORS 6D5 13 Figure 27 Testing the Pickup Coil Figure 28 Testing the Ignition Coil...

Page 696: ......

Page 698: ...7A1 2 700 R4 AUTOMATIC TRANSMISSION Figure 1 Case and External Parts J H 0 0 5 3 7 0 0 R 4 R 2...

Page 745: ...700 R4 AUTOMATIC TRANSMISSION 7A1 49...

Page 762: ...7A2 2 400 475 AUTOMATIC TRANSMISSION Figure 1 Case and External Parts H H 0021 400 R 3...

Page 773: ...400 475 AUTOMATIC TRANSMISSION 7A2 13 Figure 29 Internal Parts H H 0 0 4 3 4 0 0 R 2...

Page 797: ...400 475 AUTOMATIC TRANSMISSION 7A2 37 Figure 93 Control Valve Assem bly...

Page 803: ...400 475 AUTOMATIC TRANSMISSION 7A2 43 Figure 104 Bushing Replacement Procedure...

Page 808: ...J c I i sal...

Page 838: ......

Page 840: ......

Page 842: ......

Page 850: ...7B1 12 HM 290 MANUAL TRANSMISSION J i t i a x V L...

Page 856: ...7B1 18 HM 290 MANUAL TRANSMISSION...

Page 892: ...7B1 54 HM 290 MANUAL TRANSMISSION Figure 93 Special Tools...

Page 897: ...HM 117 TRANSMISSION 7B2 5...

Page 901: ...HM 117 TRANSMISSION 7B2 9 B 05180 Figure 17 Installing the 1st and 2nd Synchronizer...

Page 912: ...20 HM...

Page 924: ...7B3 12 NEW PROCESS TRANSMISSION SPECIAL TOOLS...

Page 927: ...BORG WARNER TRANSMISSIONS 7B4 3 Figure 2 77 mm Transmission and Components...

Page 940: ...i ii iii m i in m i...

Page 944: ...7D1 4 TRANSFER CASE FO 5688 Figure 3 NP205 Transfer Case...

Page 952: ...7D1 12 TRANSFER CASE...

Page 963: ...NEW PROCESS 241 TRANSFER CASE 7D2 11 Figure 17 Oil Pump Pickup Screen Doweled Case Holes...

Page 964: ...7D2 12 NEW PROCESS 241 TRANSFER CASE Figure 18 NP 241 Transfer Case Cut Away...

Page 978: ......

Page 981: ...BORG WARNER 1370 TRANSFER CASE 7D4 3 J...

Page 992: ...7D4 14 BORG WARNER 1370 TRANSFER CASE Figure 26 Installing the Rear Output Yoke...

Page 993: ...BORG WARNER 1370 TRANSFER CASE 7D4 15 Figure 27 BW 1370 Transfer Case...

Page 997: ......

Page 998: ...X 8937...