0020239562_04 EASICOM 3 Installation and maintenance instructions

29

9.10

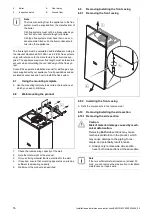

Thoroughly flushing the heating installation

("hot")

1.

Operate the appliance until the boiler and the heating

system are up to temperature.

2.

Check the heating system for leaks.

3.

Connect a hose to the drain valve located at the lowest

position of the heating system.

4.

Shut off the boiler, open the drain valve and all purge

valves on the radiators and allow the water to flow out

of the heating system and the boiler quickly and fully.

5.

Close the drain valve.

6.

Fill the heating system again with water as described in

Filling the heating installation and Purging the heating

installation.

7.

Re-fill the system until the system design pressure of

0,1 MPa (1,0 bar) is attained.

Note

The actual reading on the digital pressure

gauge should ideally be 0,05 MPa (0,5 bar)

plus an additional pressure corresponding

to the highest point of the system above the

base of the boiler

–

10 m head equals an ad-

ditional 1 bar reading on the pressure gauge.

The minimum pressure should not be less

than 0,1 MPa (1 bar) in any installation. If

the system is to be treated with an inhibitor it

should be applied at this stage in accordance

with the manufacturer’s instructions

8.

Install the front casing.

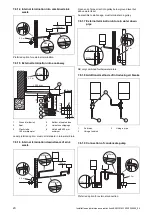

9.11

Checking leak-tightness

▶

Check the gas pipe, the heating circuit and the hot water

circuit for leak-tightness.

▶

Check that the air/flue pipe has been installed correctly.

Condition

: Room-sealed operation

▶

Check whether the vacuum chamber has been closed

tightly.

9.11.1 Checking the heating mode

1.

Activate the heating mode on the user interface.

2.

Turn all thermostatic valves on the radiators until they

are fully open.

3.

Allow the product to operate for at least 15 minutes.

4.

Purge the heating installation.

5.

Activate the display for the current operating mode.

(

Status codes

–

Overview (

◁

If the product is working correctly, the display shows

S.04.

9.11.2 Checking the domestic hot water generation

1.

Activate the domestic hot water mode on the user

interface.

2.

Open a hot water tap completely.

3.

Activate the display for the current operating mode.

(

Status codes

–

Overview (

◁

If the product is working correctly, the display shows

S.14.

10 Adapting the unit to the installation

You can reset/change the system parameters (section "Us-

ing diagnostics codes").

Overview of diagnostics codes (

10.1

Setting the burner anti-cycling time

To prevent frequent switching on and off of the burner and

thus prevent energy losses, an electronic restart lockout

is activated for a specific period each time the burner is

switched off. The burner anti-cycling time is only active for

the heating mode. Domestic hot water mode during a burner

anti-cycling time does not affect the timing element.

10.1.1 Setting the maximum burner anti-cycling

time

1.

Set diagnostics code . (

Overview of diagnostics codes (

2.

If required, change the maximum burner anti-cycling

time using the diagnostics code

d.02

.

10.1.2 Resetting the remaining burner anti-cycling

time

▶

Hold the

button down for more than 3 seconds.

◁

is shown in the display.

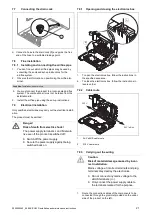

10.2

Setting the pump output

▶

If required, change the setting of the pump speed, which

depends on the operating mode, under diagnostics code

d.19

.

Overview of diagnostics codes (

Flow rate-pressure curves for 24 kW

(pressure measured downstream of the valves)

2

1

3

4

60

70

50

30

20

40

10

0

500

1000

1500 A

B

1

Maximum speed (by-

pass closed)

2

Maximum speed (de-

fault setting for the by-

pass)

3

Minimum speed (factory

setting for the bypass)

4

Flow rate at maximum

output (

Δ

T = 20K)

A

Flow rate in circuit (l/h)

B

Available pressure

(kPa)

Summary of Contents for EASICOM 3 24c

Page 1: ...en Installation and maintenance instructions EASICOM 3 24c 28c 0020239562_04 31 07 2020 ...

Page 54: ......

Page 55: ......