51

Setting the axis number (d0xxxx)

GSK driver you need to set the the axis number (1 to 30 decimal) in order to identify each axis.

Please set the following parameters to manipulate the case of a two-axis for the driver panel.

In the case of Axis 1: Write to set the axis number to d00177. (Same as 1-axis type driver)

In the case of Axis 2: Write to set the axis number to d10177.

Please set so as not to overlap with the driver axis number.

Please set the axis number to 0 (not used) or, if you do not want to connect the motor

in the two-axis type of driver.

7-2

(

d-00***, d-10***

)

Each-axis setting, driver parameter setting

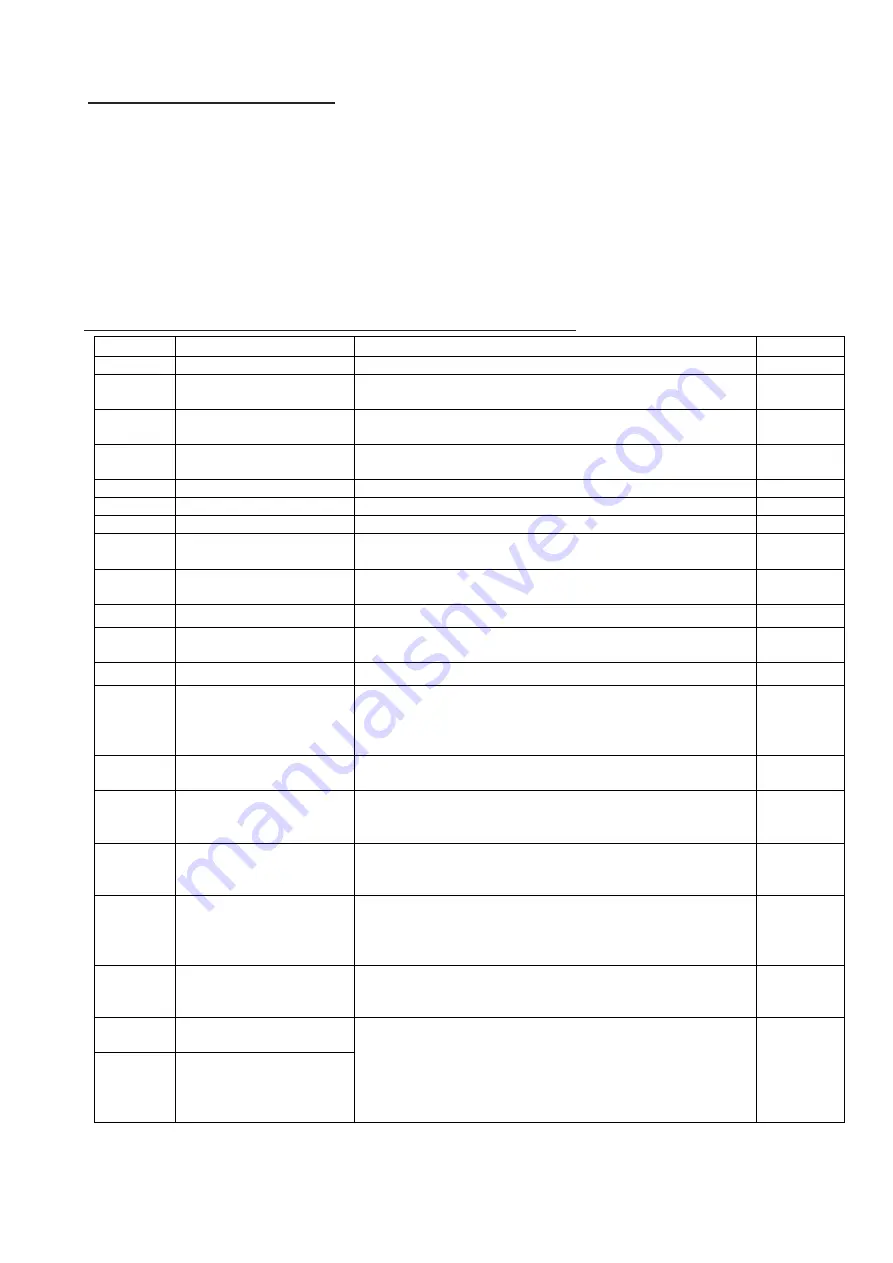

Address

Name

Matter

unit

036

Speed limit

This sets the maximum value of the rotational speed.

rpm

064

method of return to origin

0: If you are detected using the LSW and the sensor

1: butting formula

―

065

Set position data after

the return to origin

Abutment formula: return amount homing

(LSW formula: set position after homing)

―

066

Homing

start direction

Starting rotary direction of homing operation

0: positive direction 1: negative direction

―

068

Homing speed

Speed to start the homing

rpm

069

Creep rate

Origin detection rate

rpm

070

Collision time

Butting time in the origin detection of abutment type

msec

071

Collision torque

Butting

torque

in the origin detection of abutment type

Please set as a percentage of the motor rated current

%

084

ID of the monitor 1

Data of the set ID is converted into an analog signal that it

‘s outputted from the M1 terminal.

―

085

Scale of the monitor 1

Output scaling of the monitor 1

―

086

ID of the monitor 2

Data of the set ID is converted into an analog signal that it

‘s outputted from the M2 terminal.

―

087

Scale of the monitor 2

Output scaling of the monitor 2

―

104

Detection current of

overload alarm

The alarm becomes overloaded when the average value of

the motor current exceeds the set value.

Setting value is set as a percentage of the motor rated

current.

%

105

Detection rate of

Acceleration alarm

The number of revolutions of the motor

rpm

142

Magnification of the

sensor resolution

It sets the resolution magnification of the sensor.

NR, positioning encoder, positioning resolver: 4

―

160

Gear abnormality

determination count

(continuous)

When the gear failure is detected, it will set the number of

times determined to the alarm.

―

161

Gear abnormality

determination count

(cumulative)

It sets the resolution of the sensor

NR: 256, Positioning resolver: 8192

Positioning encoder: 16384

NR2: 1024

―

163

Temporary tightening

torque-free monitoring

time

This sets the torque-free monitoring time of the

pre-tightening.

msec

165

Minimum gradient

determination value

It is judged to be abnormal when the gradient is less than

the value obtained by multiplying the value of -1 to be set

here.

Here you set the rapid torque change rate that it is

generated by a bolt

breakage

at the time of this tightening

end.

%

%

166

Bolt fracture criterion

value

Summary of Contents for GSK Series

Page 1: ...Instruction Manual GSK GSKW Controller November 2017 GIKEN INDUSTRIAL CO LTD The 3rd edition...

Page 16: ...15 Size Interface dimensions Standard type GSK IF...

Page 17: ...16 Controller dimensions Standard type GSK 4 GSKW 4...

Page 18: ...17 Controller dimensions Standard type GSK 5 7...

Page 19: ...18 Controller dimensions T type GSK T5 T7...

Page 20: ...19 Controller dimensions Standard type GSKW 5...

Page 21: ...20 Controller dimensions T type GSKW T5...

Page 22: ...21 Dimensions display Model GSK D1 Panel cut out dimensions Back Side Front Under...

Page 24: ...23 M net ver GSK Controller system wiring reference diagram...

Page 28: ...27 External connection diagram I F unit Connected equipment standard and T type...

Page 50: ...49 Setting...

Page 58: ...57 Reverse tightening reference waveform...

Page 62: ...61...

Page 63: ...62 Gradient calculation method...