Grid: Velocity Profile Test Grid 6" from back and sides,

6 3/4" from front

LFGI 3 & 4, 5 5/8" apart left to right, 6" apart front to back

LFGI 6, 6" apart left to right, 6" apart front to back

Note: Above grid measurements made on work tray correspond to proper location at 12”

below diffuser.

Particle Counts

The LFGI USP should maintain ISO Class 5 conditions in the work environment regardless

of pressurization. To verify, divide the work tray into 1 square foot areas and sample the

center of each zone for a minimum of 1 minute per zone.

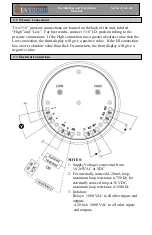

Filter Integrity

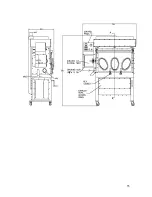

The unit has two main HEPA filters, one above the work zone (supply) and one below

(exhaust), see figure 1. The Supply HEPA filter should be scanned with a Photometer while

challenged with DOP or equivalent. The aerosol challenge can be introduced to the

upstream side of the HEPA filter through the supply blower inlet. An upstream challenge

can be read through the port opposite the LFGI control panel by removing the hex head

plug. If access to the side of the unit is not possible, the upstream challenge can be read

through the port inside the control panel connected to the “supply HEPA filter” pressure

gauge. For the exhaust HEPA filter the challenge is introduced into the work area and a

mass flow reading should be measured in the air recycle plenum on the back top of the unit.

All HEPA filters are 99.99%.

Fig.1 Supply filter access (left) and Exhaust filter access (right)

62

Summary of Contents for LFGI-3USP

Page 1: ...Laminar Flow LFGI CAI or CACI User Manual ...

Page 33: ...33 ...

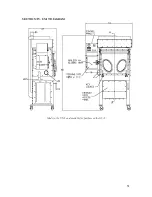

Page 51: ...SECTION IV UNIT DIAGRAM Made in the USA and available for purchase on the GSA 51 ...

Page 55: ...55 ...

Page 59: ...59 ...

Page 63: ...Fig 2 Air recycle plenum connection tip removed 63 ...

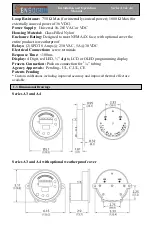

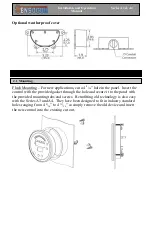

Page 85: ... 863 248 2800 www sensocon com 20 Installation and Operation Manual Series A3 A4 ...