the sleeve O-ring over the new sleeve to secure it. Reach inside of the glovebox with the

other glove and pull the old sleeve off and into the work area. Dispose of Sleeve through

the airlock.

Glove and Sleeve Inspections

A visual inspection of all glove and sleeve surfaces is recommended at the beginning and end

of each day. Any tears or punctures would require a replacement.

If the unit is operating and is under pressure the operator can run a hand on all surfaces to

feel for any air moving into or out of the work area through imperfections in the surfaces.

Soap solution can also be used. If the LFGI has pressure the soap will bubble at any cut,

tear or puncture.

39

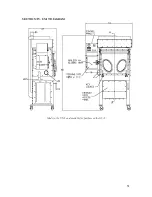

Summary of Contents for LFGI-3USP

Page 1: ...Laminar Flow LFGI CAI or CACI User Manual ...

Page 33: ...33 ...

Page 51: ...SECTION IV UNIT DIAGRAM Made in the USA and available for purchase on the GSA 51 ...

Page 55: ...55 ...

Page 59: ...59 ...

Page 63: ...Fig 2 Air recycle plenum connection tip removed 63 ...

Page 85: ... 863 248 2800 www sensocon com 20 Installation and Operation Manual Series A3 A4 ...