Maintenance and Repair

4 - 25

4.16

Flow Restrictor Maintenance

(Models OP300 through OP500)

WARNING!

Ensure that the dryer and any associated prefilters

and afterfilters are valve isolated and fully depressur-

ized before attempting to remove or disassemble any

components or subassemblies. Failure to do so may

result in serious personal injury and/or equipment

damage.

1.

Clean and inspect the assembly. Check operation of

the assembly. If a tendency to bind, erratic operation,

damage and/or excessive wear is noted, disassemble

and repair the assembly.

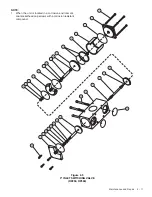

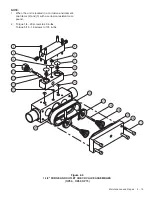

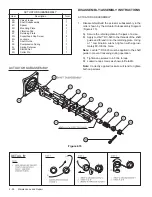

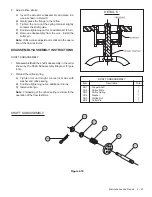

DISASSEMBLY/ASSEMBLY INSTRUCTIONS

1.

Disassemble/Build the flow restrictor assembly in the

order shown by the Flow Restrictor Assembly Diagram

(Figure 4.14).

A) Hand tighten studs in sequence shown in Detail A.

B) Tighten studs in sequence shown to 30 ft-lbs.

torque.

C) Leak check valve.

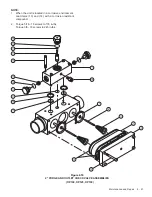

FLOW RESTRICTOR ASSEMBLY

FLOW RESTRICTOR ASSEMBLY

Item

Description

Total

1

Valve Body

1

2

Actuator Subassembly

1

3

Valve Flange

1

4

O-Ring

2

5

Hex Nut

8

6

Threaded Stud

4

DETAIL 'A'

Figure 4.13

Figure 4.14