4 - 4

Maintenance and Repair

7.

LIGHTLY lubricate the new O-ring with a petroleum-

based lubricant that is compatible with your applica-

tion before installing the new element.

8.

Insert new element, snapping it into place with a firm

push up into the head. The element will hang from

the head until the bowl is installed.

9.

LIGHTLY lubricate the housing O-ring with a petro-

leum-based lubricant that is compatible with your ap-

plication.

CAUTION: Do not use a pipe wrench to tighten the

filter bowl to the head.

10. Reattach bowl to head and hand tighten. As the bowl

is threaded onto the head, supports in the bottom of

the bowl ensure a proper seal between the element

and the filter head.

11. Reattach drain lines (if applicable).

12. Close service valve.

13. Slowly open the inlet isolation valve to prevent a pres-

sure surge through the filter.

14. Once the filter has been pressurized, slowly open the

outlet isolation valve.

15. After both isolation valves have been opened, close

the system bypass valve. The filter is now in service.

16. Record the date of the element change in a record

book or on the provided "Element Change" label. A

new element change label with the updated informa-

tion should be applied over the previous label each

time the element is replaced.

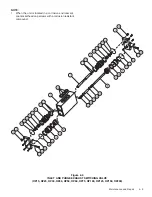

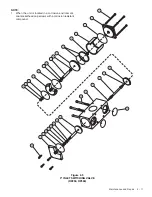

Dryer Models OP300 through OP500

WARNING!

Ensure that the Dryer and any associated Prefilters

and Afterfilters are valve isolated and fully depressur-

ized before attempting to remove or disassemble any

components or subassemblies. Failure to do so may

result in serious personal injury and/or equipment

damage.

1.

Isolate the filter by opening the system bypass valve

(refer to Figure 2.1, page 2-2), and closing both inlet

and outlet isolation valves.

2.

Open the service valve to vent the filter to atmo-

spheric pressure.

3.

Disconnect drain lines at manual and automatic drain

valves (if installed).

4.

Remove the bolts securing the filter cover to the ves-

sel.

5.

Remove the filter cover.

6.

Unscrew and remove cartridge retaining seal nuts.

7.

Remove the used element cartridges. Discard the

cartridges in accordance with applicable regulations.

Used elements typically hold contaminants, such as

compressor lubricants and particulate matter.

8.

Insert new element cartridges in filter.

9.

Reinstall element seal nuts. Screw seal nuts on until

"hand-tight", then tighten an additional one-half (1/2)

turn.

10. Replace filter cover.

11. Reinstall bolts to secure filter cover.

12. Reattach drain lines (if applicable).

13. Close service valve.

14. Slowly open the inlet isolation valve to prevent a pres-

sure surge through the filter.

15. Once the filter has been pressurized, slowly open the

outlet isolation valve.

16. After both isolation valves have been opened, close

the system bypass valve. The filter is now in service.

17. Record the date of the element change in a record

book or on the provided "Element Change" label. A

new element change label with the updated informa-

tion should be applied over the previous label each

time the element is replaced.

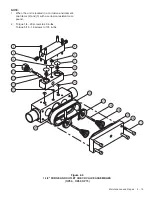

4.4

Servicing The Internal Float

Drain Valve (If Equipped)

WARNING!

Ensure that the Dryer and any associated Prefilters

and Afterfilters are valve isolated and fully depressur-

ized before attempting to remove or disassemble any

components or subassemblies. Failure to do so may

result in serious personal injury and/or equipment

damage.

1.

Isolate the filter by opening the system bypass valve

(refer to Figure 2.1, page 2-2), and closing both inlet

and outlet isolation valves.

2.

Open the service valve to vent the filter to atmo-

spheric pressure.

3.

Disconnect drain lines and automatic drain valves (if

installed).

WARNING!

A "hissing" sound while the bowl is being removed

indicates the filter has not been properly depressur-

ized. DO NOT continue to remove the bowl until the

filter has been completely vented to atmospheric pres-

sure.