3 - 2

Operation

leaks, (no matter how small), detected at, or down-

stream of the dryer outlet MUST BE FIXED to ensure

that the dryer will provide a continuous supply of pro-

cess gas at specified dew point, to intended points-of-

use.

IMPORTANT: Water molecules can diffuse through

a pinhole-size leak even though pressure inside the

piping is several hundred PSIG. It is not uncommon

to have a minute pinhole leak in a gas line cause an

increase in dew point from -40°F to -10°F at a dis-

tance of forty or more feet downstream of the leak.

13. SLOWLY open the customer-supplied System Outlet

Isolation Valve, while monitoring the Outlet Pressure

Gauge (if dryer so-equipped). DO NOT permit the

Dryer's Outlet Pressure Gauge to exceed a 5% drop

in pressure while pressurizing downstream piping.

14. Close the customer-supplied System Bypass Valve (if

installed).

15. Open and adjust the Moisture Indicator’s Bleed Valve

until a very slight, continuous gas bleed is felt ex-

hausting from the bleed valve’s exhaust port. Ensure

that the granular indicator crystals remain motionless

after final adjustment.

16. Energize the dryer’s electrical power supply.

17. PURGE SETTING AND ADJUSTMENT

a) Locate the Critical Orifice Calibration Curve in

Appendix A of this manual.

b) To calculate purge flow consumption on the criti-

cal orifice curve:

Inlet Flow (SCFM) × 14.7 PSIG

× 1.15 = Purge (SCFM)

Inlet Pressure (PSIG) + 14.7 PSIG

Cross the Purge Flow requirement calculated

above to the same number on the Critical Orifice

Calibration Curve. Follow this line vertically and

then horizontally once intersection is made with

the curve line to find the actual purge pressure

setting.

18. Locate the Purge Adjusting Valve. Slowly rotate

dryer’s Purge Adjusting Valve until the Purge Pres-

sure Indicator indicates the calculated purge pressure

setting. (See following Note).

Note: The purge pressure can only be read and ad-

justed when an off-stream desiccant chamber has

depressurized for regeneration. (When the off-

stream chamber is pressurized, the Purge Pressure

Indicator will read “system pressure”.)

For dryers with the OPTITEK 2 EMS Energy Manage-

ment System: During operation in the Energy Man-

agement Mode, the off-stream chamber may remain

pressurized (in ENERGY MANAGEMENT ACTIVE).

If this condition is noted, proceed as follows to adjust

purge pressure.

a) Open Dryer Control System Enclosure. Locate

DIP switches on MEC CPU Board.

b) Switch DIP switch position 7 to OFF position

(down). De-energize dryer’s electrical power

supply for approximately fifteen (15) sec-

onds; then re-energize. Dryer is now in Fixed

Cycle Operation. The off-stream chamber will

depressurize to atmosphere for regeneration.

c)

Calculate and set purge pressure as previously

instructed.

d) Return DIP switch position 7 to ON position. De-

energize the dryer’s electrical power supply for

approximately fifteen (15) seconds; then re-ener-

gize. Dryer should be in Optitek Energy Saver

Mode.

19. The Start-Up procedure for models OP15 through

OP200 is now complete. Proceed to the Normal Op-

eration Checks section of this manual for final opera-

tional checks and adjustments.

Dryer Models OP250 and OP300

1.

Close any manual vent or drain valves installed in

prefilter and afterfilter assemblies.

2.

If the prefilter assembly utilized was factory-equipped

with an automatic drain valve or drain trap, inspect

for, and remove pipe plug or cap which may have

been installed in drain port for shipping purposes.

3.

Ensure that all associated pipe and tubing connec-

tions, flanges, unions, plugs, mounting bolts, pipe

hangers, etc., have been checked tight and/or prop-

erly secured.

IMPORTANT: It is recommended that the System's

process gas output not be consumed or used at the

intended points of use until the Start-Up and any re-

lated adjustments have been completed, and the sys-

tem is producing process gas of the required quality.

The quality of the process gas should be verified

through test and analysis when a specific quality pro-

cess gas is required.

4.

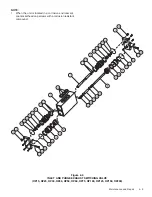

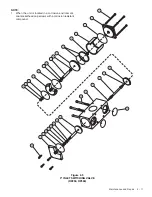

Refer to the applicable drawings which accompany

this manual as necessary for component identification

and location while conducting start-up and operational

procedures.

Note: If your dryer cannot be started, or fails to start

due to special installation or other problems, contact

your local General Pneumatics Sales Representative

for assistance.