Installation

Automatic Transfer Switch Owner’s Manual

7

NOTE:

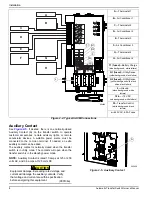

A Neutral to Ground bonding screw (A) is

provided for use if required by local codes.

Conductor sizes must be adequate to handle the

maximum current to which they will be subjected, based

on the 75°C column of tables, charts, etc. used to size

conductors. The installation must comply fully with all

applicable codes, standards and regulations.

All power cables can enter the enclosure through the

provided knockouts. Additional knockouts into the

transfer switch can be made in the field as needed.

Conduit entry shall maintain the proper wire bending

spaces required by Tables 312.6 (A) and (B) in the NEC.

Conduits should be arranged to provide separation

between the Utility and Generator supply conductors

inside the enclosure.

NOTE:

If aluminum conductors are used, apply corrosion

inhibitor to conductors. After tightening terminal lugs,

carefully wipe away any excess corrosion inhibitor.

Tighten terminal lugs to the torque values as noted on the

decal located on the inside of the door. After tightening

terminal lugs, carefully wipe away any excess corrosion

inhibitor.

Connecting Start Circuit Wires

Control system interconnections consist of N1, N2, and

T1, and leads 23, 194, and 9 (Ground). The connections

are color coded on the load shed to match connections in

the Generac genset. Generac cable tray cable includes

power cables with all necessary color-coded control

wiring. It is suitable for direct burial, overhead and indoor

wiring.

The generator control wiring is a Class 1 signaling circuit.

Reference instruction manual of specific engine

generator for wiring connection details. Recommended

wire gauge sizes for this wiring depends on the length of

the wire, as recommended in the following chart:

Exception:

Conductors of AC and DC circuits, rated

1000 volts nominal, or less, shall be permitted to occupy

the same equipment, cable, or conduit. All conductors

shall have an insulation rating equal to at least the

maximum circuit voltage applied to any conductor within

the equipment, cable, or conduit. See NEC 300.3(C)(1).

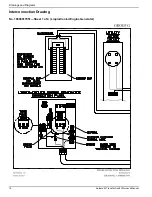

Connecting SACM

See

. The SACM can control an air conditioner

(24 VAC) directly.

Control of Air Conditioner Load

1.

Route the thermostat cable (from the furnace/

thermostat to the outdoor air conditioner unit) to the

transfer switch.

2.

Connect the wire to the terminal strip terminals

(A/C 1) on the SACM as shown in

These are normally closed contacts which open

upon load shed conditions. Route thermostat wire

away from high voltage wires.

3.

If required, connect additional air conditioners to

the terminal strip terminals (A/C 2-4).

NOTE:

These instructions are for a typical air conditioner

installation. Control of certain heat pumps and 2-stage air

conditioners may require special connections or the use

of SMMs to control the loads.

Maximum Wire Length

Recommended Wire Size

1–115 ft (1–35 m)

No. 18 AWG

116–185 ft (36–56 m)

No. 16 AWG

186–295 ft (57–89 m)

No. 14 AWG

296–460 ft (90–140 m)

No. 12 AWG

(000120)

CAUTION

Equipment damage. Verify all conductors are tightened

to the factory specified torque value. Failure to do so

could result in damage to the switch base.

Contact Ratings

A/C 1-4

24 VAC, 1.0 Amp Max

Summary of Contents for RXSW200A3F

Page 4: ...iv Automatic Transfer Switch Owner s Manual This page intentionally left blank ...

Page 8: ...Safety 4 Automatic Transfer Switch Owner s Manual This page intentionally left blank ...

Page 14: ...Installation 10 Automatic Transfer Switch Owner s Manual This page intentionally left blank ...

Page 27: ......