22

Owner’s Manual for Mobile Light Tower

Maintenance

Figure 4-1. Proper Mast Cable Routing

•

Verify safety pins for the mast lock rod and mast

lock bar are present and secured with a chain.

Verify the mast lock bar spring is not broken or

missing. Check the operation of the mast lock bar.

•

Verify the wheel lugs are present and properly

tightened. Refer to

.

•

Check coolant level daily. Normal operating level is

between the ‘full’ and ‘add’ markings on the

overflow jug. Refer to the engine operator’s manual

for coolant recommendations and proper mixture.

•

AFTER ENGINE IS STOPPED AND

COMPLETELY COOL

, coolant may be added

directly to the coolant overflow jug.

•

Check oil level daily. Refer to the engine operator’s

manual for the appropriate oil specification. Verify the

oil is correct for special operating conditions such as a

change in season or climate.

•

DO NOT

start the unit if the engine oil level is below

the add mark on the dipstick.

•

Normal operating level is in the cross-hatch pattern

between the full and add markings on the dipstick.

•

Add oil only if the oil level is below the add mark on

the bottom of the cross-hatch pattern on the dipstick.

DO NOT OVERFILL

the crankcase.

•

Check the fuel level.

•

If the unit is connected to a remote start or transfer

switch, verify the remote switch is off and tagged.

Basic Maintenance Schedule

Refer to the original equipment manufacturer’s operating manual for a complete list of maintenance requirements.

Failure to comply with the procedures as described in the engine operator’s manual will nullify the warranty, decrease

performance and cause equipment damage or premature failure. Maintenance records may be required to complete a

warranty request. Use the schedule in the following table as a guide for regular maintenance intervals. For additional or

replacement copies of the engine operator’s manual, contact a GMASD.

*

Perform after the initial 50 hours of operation, then on the regularly scheduled interval indicated in the schedule above.

**

Certain conditions may require the fuel tank to be drained and cleaned more often. When operating in extremely

dusty conditions, clean the fuel tank as often as necessary.

Basic Maintenance Guide (Mitsubishi Engine)

ITEM

DAILY

50

Hr

250

Hr

400

Hr

500

Hr

750

Hr

1,000

Hr

Check oil level

Check coolant level

Check fuel level

Check tire pressure

Check all electrical connections

Inspect radiator fins for debris, clean as required

Inspect light tower winch for proper operation

Fuel tank - drain water

Check air cleaner

Belt and belt tension - inspect and adjust

Replace fuel filter

Drain and clean fuel tank

**

Check glow plugs

Lubricate leveling jacks

Replace engine oil and oil filter

*

Bolts and nuts on the engine - retighten

*

Replace heated fuel filter (if equipped)

Inspect engine starting battery

Summary of Contents for MLT4060KV

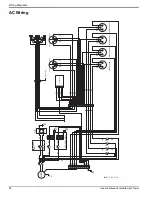

Page 4: ...iv Owner s Manual for Mobile Light Tower Trailer Lights Wiring 33 ...

Page 24: ...20 Owner s Manual for Mobile Light Tower Operation This page intentionally left blank ...

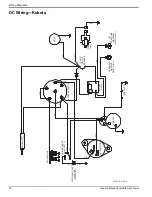

Page 35: ...Owner s Manual for Mobile Light Tower 31 Wiring Diagrams DC Wiring Electric Winch ...

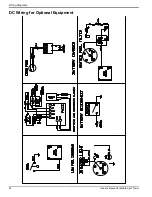

Page 36: ...32 Owner s Manual for Mobile Light Tower Wiring Diagrams DC Wiring for Optional Equipment ...

Page 38: ...34 Owner s Manual for Mobile Light Tower Wiring Diagrams This page intentionally left blank ...

Page 39: ......