8. Pull o

ff

handwheel

H

from the threaded

spindle.

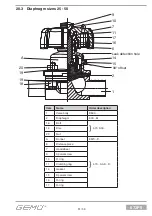

9. Position distance piece

4

(bevel

downwards) on the threaded spindle and

screw it down clockwise until it sits on

the valve bonnet.

4

4

Diaphr. size 8

Diaphr. size 10

4

Diaphragm sizes 25- 50

10. Push handwheel

H

in its original position

on the square of the threaded spindle

(observe the teeth of the adjusting ring

4

and the handwheel

H

). Tighten it with

special screw

6

(insert O-ring

10

if

existing).

6

H

H

6

10

Diaphr. size 8

Diaphragm size 10

H

6

Diaphragm sizes 25- 50

10.4 Autoclaving the valve

CAUTION

High temperatures during autoclaving!

®

Damage to seals.

G

Move the bonnet to the open position.

G

Before autoclaving ensure that special

screw

15

is tightened hand tight (only

for diaphragm sizes 25 - 50).

Diaphragm sizes 8 and 10 have no

leak detection hole.

10.4.1 Autoclaving valves with

diaphragm sizes 8 - 10

1. Move bonnet

A

to the open position.

2. Autoclave valve

A

.

10.4.2 Autoclaving valves with

diaphragm sizes 25 - 50

A

15

1. Move bonnet

A

to the open position.

2. Hand tighten special screw

15

without

tools.

3. Autoclave valve

A

.

4. Loosen special screw

15

after

autoclaving.

Only loosen special screw

15

where this is necessary for the

further work process.

39 / 56

673P9

Summary of Contents for 673P9 Series

Page 27: ...27 56 673P9...

Page 53: ...53 56 673P9...

Page 54: ...54 56 673P9...

Page 55: ...55 56 673P9...