FAULT

CAUSE

REMEDY

F All cylinders out of

action while compressor

is operating

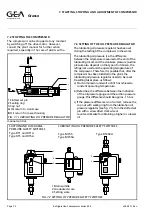

1. Control pressure for valve lifting mechanism

too low

1. See K

G Too high oil

consumption

1. Type of oil not according to lubrication oil

table 3.1 (too thin oil)

1. Consult installation engineer

2. Compressor operates onloaded too

frequently

2. Consult installation engineer

3. No return from oil separator

3. Check the operation of float valve

in oil separator

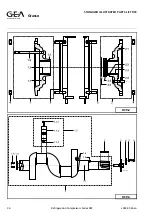

4. O-rings around control piston of valve lifting

mechanism worn or defective

4. Replace O-rings

5. Non-return valve at the bottom of suction

chamber in cylinder defective

5. Replace valve*

6. Worn out oil scraper rings

6. Replace rings*

7. Loss of oil due to leakage

7. Repair

H Too high oil pressure

during normal

operation at working

temperature

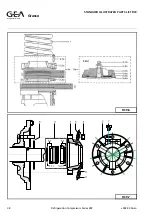

1. Lubricating oil pressure regulator not

adjusted properly or defective

1. Re-adjust or repair

2. Defective oil pressure and/or suction

pressure gauge

2. Repair or replace

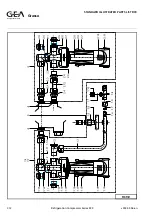

J Too low oil pressure

1. Tool little amount of oil in crankcase

1. Top up oil

2. Oil suction and/or discharge filter is dirty

2. Clean or renew

3. Lubricating oil pressure regulator not

adjusted properly or defective

3. Re-adjust or repair

4. Liquid refrigerant in crankcase

4. See E

5. Defective oil pressure and/or suction

pressure gauge

5. Repair or replace

6. Too large bearing clearance

6. Renew bearings*

K Too low or no control

pressure

1. Hydraulic time delay valve in oil pump is

jammed

1. Dismantle and repair oil pump*

2. Relief valve in oil pump leaks

2. Disassemble and repair valve

The operation marked with an * in the column "Remedy" should be carried out by the installation engineer

Refrigeration Division

Grasso

10. FAULT FINDING TABLE

Page 10.2

Refrigeration Compressors Series RC9

v002.97.10.en