7.2 STOPPING THE COMPRESSOR

The compressor can be stopped at any moment

by switching off the drive motor. However,

consult the plant manual for further action

required, especially in the case of plants with a

manual control.

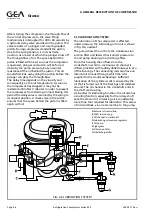

7.3 SETTING OF THE OIL PRESSURE REGULATOR

The lubricating oil pressure regulator has been set

during the testing of the compressor in the works.

The lubricating oil pressure (i.e. the difference

between the oil pressure measured at the end of the

lubricating circuit, and the crankcase pressure (suction

pressure also depends on the type of oil chosen, the

refrigerant used and the operating temperature of

the compressor. Therefore it is possible that, after the

compressor has been installed in the plant, the

lubricating oil pressure regulator needs to be reset.

Re-setting takes place as follows:

a) Start compressor and wait until it has achieved a

constant operating temperature.

b) Determine the difference between the indication

of the oil pressure gauge and the suction pressure

gauge. This difference should be approx. 1.5 bar.

c) If the pressure difference is not correct, remove the

cap nut with sealing ring from the lubrication oil

pressure regulator (see fig. 7.1).Turn the slotted set

pin with a screw driver clockwise or

counter-clockwise for obtaining a higher or a lower

oil

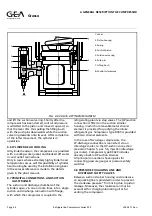

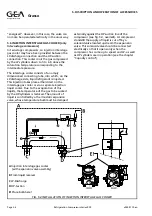

FIG. 7.1 LUBRICATING OIL PRESSURE REGULATOR

Refrigeration Division

Grasso

A

B

1

2

3

1 Slotted set pin

2 Sealing ring

3 Cap nut

A

Oil return to crankcase

B

Oil return from seal housing

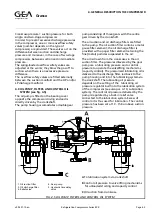

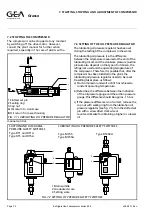

FIG. 7.2 SETTING OF PRESSURE SAFETY SWITCHES

1

3

2

3

2

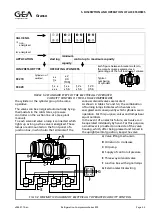

LUBRICATING OIL PRESSURE SAFETY SWITCHES

Type MP55 Type RT260A

Type MP55A

1 Main spindle

2 Graduated scale

3 Setting scale

SUCTION AND DISCHARGE

PRESSURE SAFETY SWITCHES

Type RT1 and RT1A

Type RT5 and RT5A

7. STARTING, STOPPING AND ADJUSTMENT OF COMPRESSOR

Page 7.2

Refrigeration Compressors Series RC9

v002.97.10.en