9

09665

-0

8.

20

18-

Gb

Maintenance

Service intervals

Practically no maintenance is required. However, for an optimal operating safety and service life of the compressor

we recommend

to

carry out the necessary maintenance work regularly according to the specifications of the manufacturer of the refrigerating plant.

5 I Maintenance

Function checks to be carried out once a year

Leak test of the plant

Checking the running noise of compressor

Checking pressures and temperatures of the plant

Checking the tensioner for orderly seating

Checking the V belts for tension and condition

Checking the oil level in the crankcase

Checking the fixing screws for tightening

Checking the function of the ancillary units

Checking the electrical connections for clean, firmly fixed contacts and the leads for chafing points

Oil level check

After starting the compressor, the oil level has to be checked. For this:

The driving engine should be in the „High idle“ operating condition (elevated idling speed)

Compressor running time at least 10 min.

The plant should have reached the operating point

The oil level must be visible in the sight glass

Changing oil

In case of orderly manufactured and operated plants an oil change is in principle not absolutely necessary.

Yet, based on decades-long experience we recommend to carry out the following oil change and servicing.

- First oil change at the first maintenance of the vehicle.

- After that, changing the oil every 5000 operating hours, but at the latest after 3 years.

At the same time the oil filter and the suction filter should be cleaned and the oil collecting ring

from the shaft seal replaced.

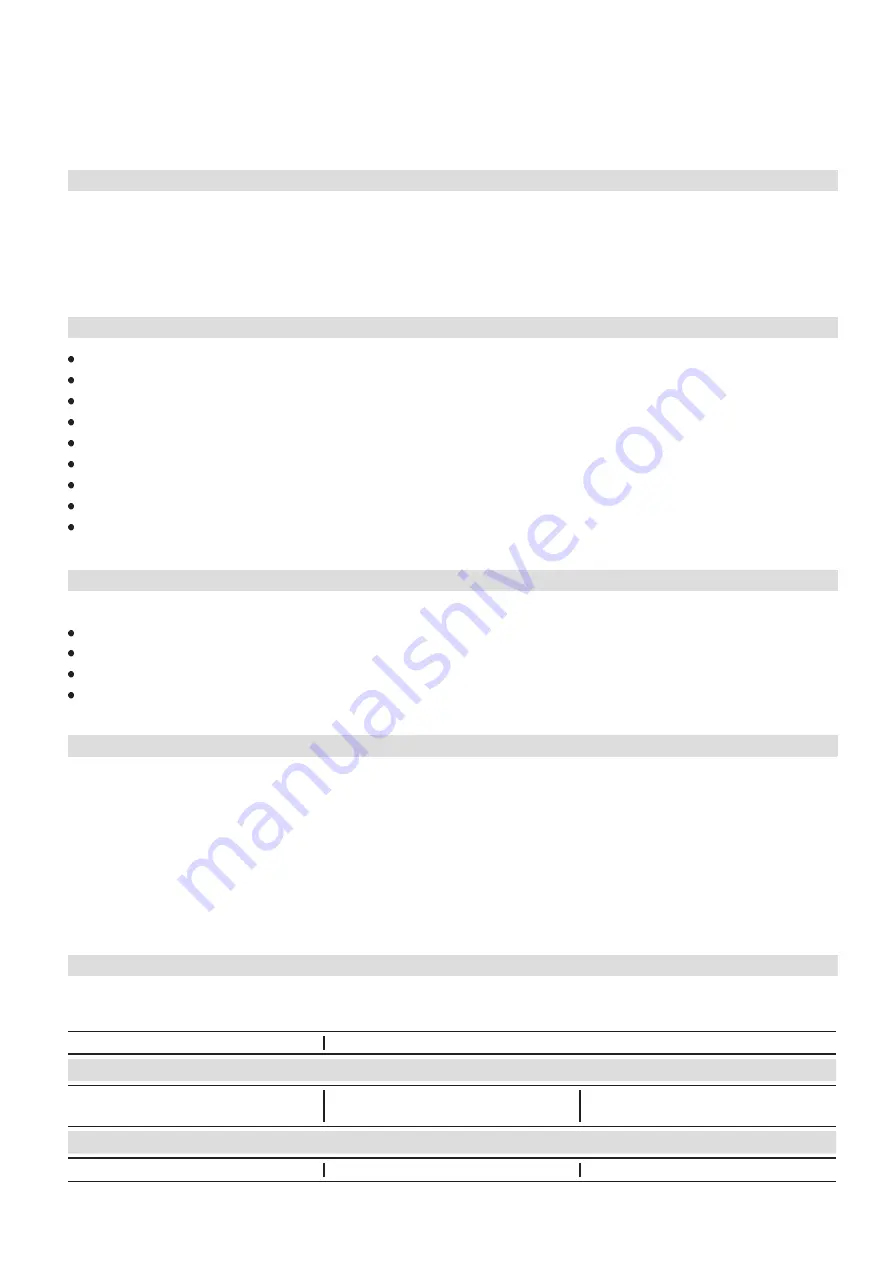

Standard oil type used by GEA Bock

Recommended alternatives

For HCFC (e.g. R22)

Fuchs Reniso SP 46

BP Energol LPT 46

SUNOCO Suniso 3.5GS

TEXACO Capella WF 46

For HFC (e.g. R134a, R404A, R407C)

Fuchs Reniso Triton SE 55

FUCHS SEZ 32 / 68 / 80

ESSO / Mobil EAL Arctic 46

Lubricants

Information about other suitable oils should be taken from GEA Bock lubricant tables. Information may also be retrieved from vap.gea.com

(mobile applications -> documentation -> technical information -> vehicle compressor -> ... -> lubrication chart).

The oil type charged as standard in the factory is marked on the

name plate. This oil type should be used as a preference.

Alternatives are stated in the extract from our lubricants table below: