Electromagnetic Compatibility (EMC)

EMC Immunity Test (cont'd.)

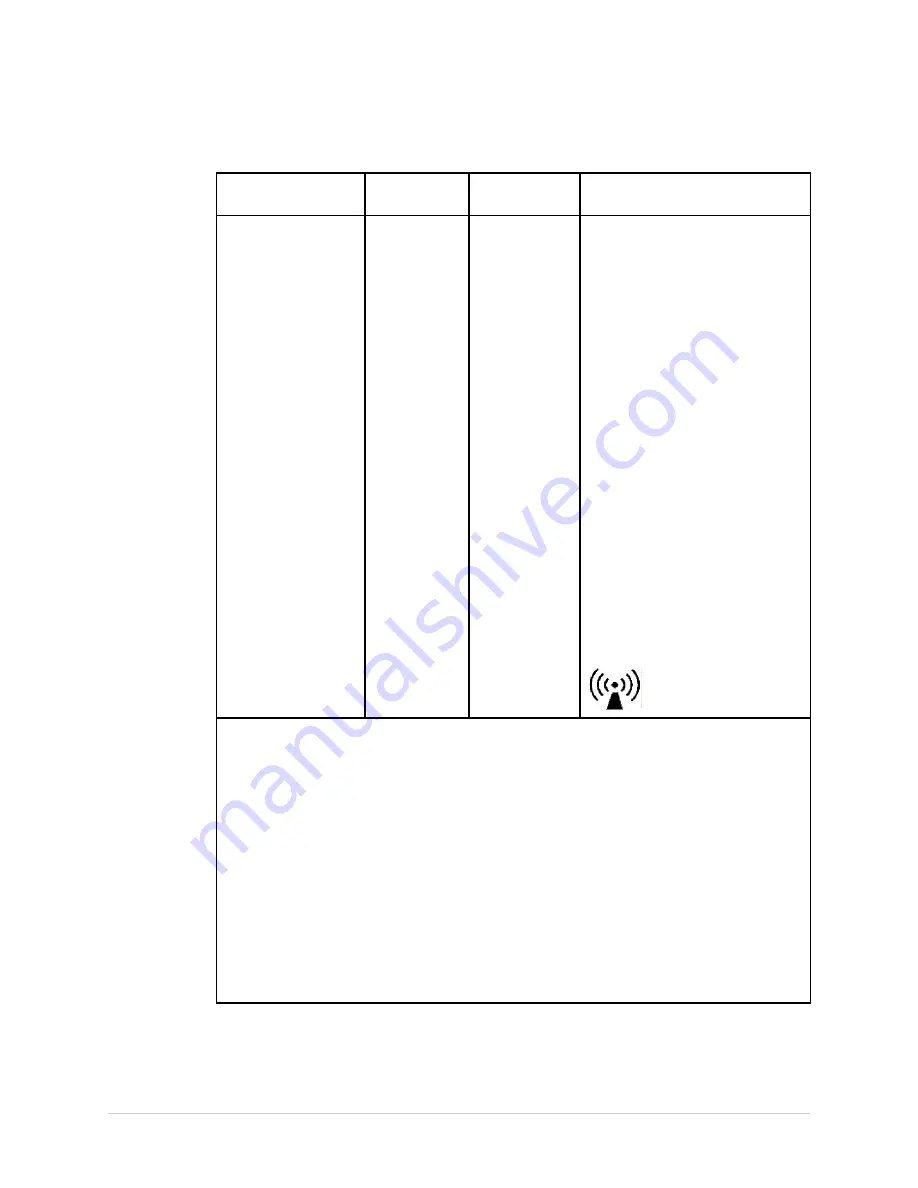

Immunity Test

Compliance

Test Level

Compliance

Level

Electromagnetic

Environment–Guidance

Radiated RF

3 V/m

80 MHz to 2.5

GHz

@ 2 Hz mod.

Multilink Lead

set: 3.0 V/m

Value Lead set:

3.0 V/m

KISS Lead set:

1.0 V/m

Multilink Lead Set:

d = 1.2 √P 80 MHz to 800 MHz

d = 2.3 √P 800 MHz to 2.5 GHz

Value Lead Set:

d = 1.2 √P 80 MHz to 800 MHz

d = 2.3 √P 800 MHz to 2.5 GHz

KISS Lead Set:

d = 3.5 √P 80 MHz to 800 MHz

d = 7 √P 800 MHz to 2.5 GHz

Recommended separation

distance:

where

P

is the maximum output

power rating of the transmitter

in watts (W) according to the

transmitter manufacturer, and

d

is the recommended separation

distance in meters (m).

Field strengths from fixed RF

transmitters, as determined by an

electromagnetic site survey:

a

should be less than the

compliance level in each

frequency range

b

Interference may occur in the

vicinity of equipment marked with

the following symbol:

NOTE:

• At 80 MHz and 800 MHz, the higher frequency range applies.

• These guidelines may not apply in all situations. Electromagnetic propagation is

affected by the reflection from structures, objects, and people.

•

a

Field strengths from fixed transmitters, such as base stations for radio

(cellular/cordless) telephones and land mobile radio, AM and FM radio broadcast,

and TV broadcast cannot be predicted theoretically with accuracy. To assess the

electromagnetic environment due to fixed RF transmitters, consider conducting an

electromagnetic site survey. If the measured field strength in the location in which

the system is used exceeds the applicable RF compliance level listed in this table,

observe the system to verify normal operation. If abnormal performance is observed,

additional measures may be necessary, such as re-orienting or relocating the system.

• Over the frequency range 150 KHz to 80 MHz, field strengths should be less than 3

V/m for Multilink and Value Lead Sets, and less than 1 V/m for the KISS Lead Sets.

2053535-003C

MAC™ 2000 ECG Analysis System

169

Summary of Contents for MAC 2000

Page 41: ...Product Overview 2053535 003C MAC 2000 ECG Analysis System 41 ...

Page 134: ...Maintenance 134 MAC 2000 ECG Analysis System 2053535 003C ...

Page 160: ...Parts List 160 MAC 2000 ECG Analysis System 2053535 003C ...

Page 182: ...182 MAC 2000 ECG Analysis System 2053535 003C ...

Page 183: ......