Troubleshooting

Visual Inspection Checklist (cont'd.)

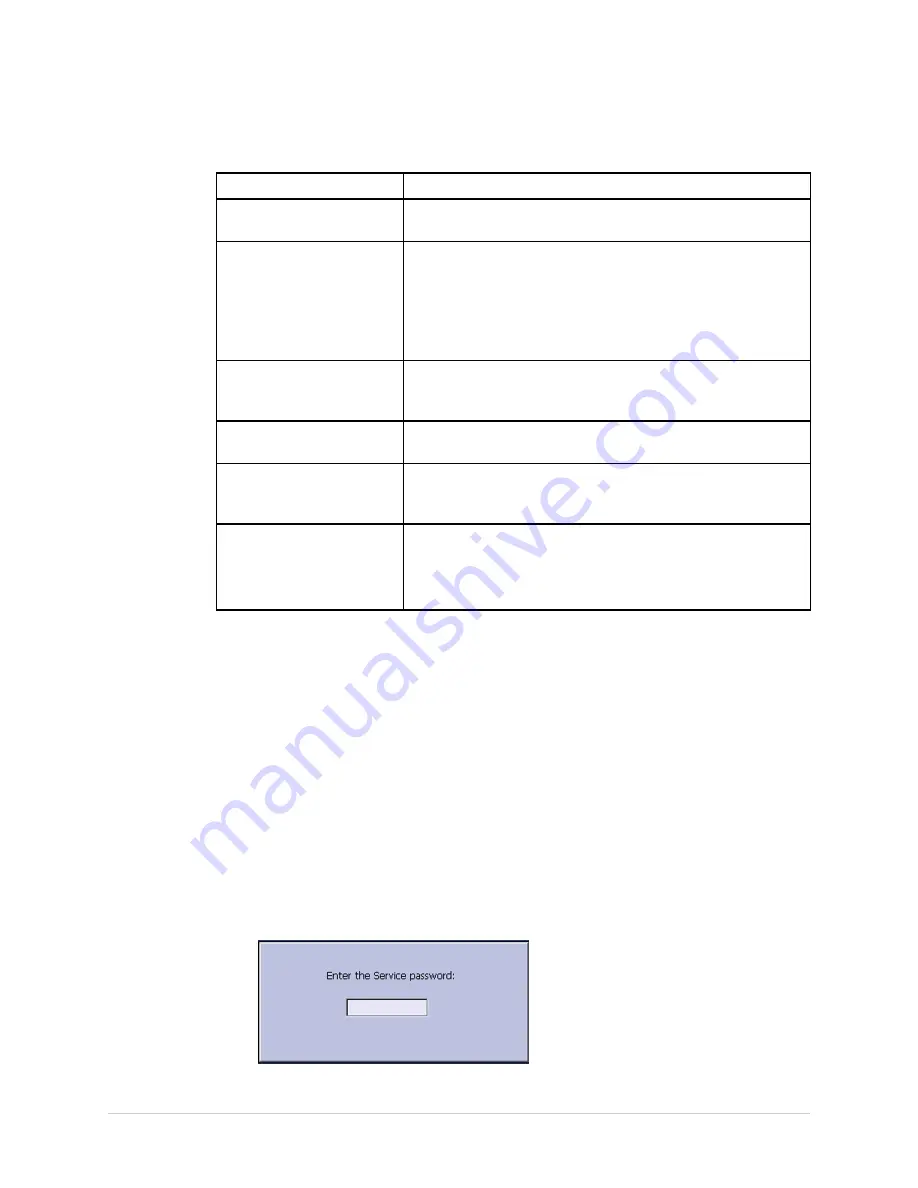

Area

Look for the following problems

Fasteners

Loose or missing screws or other hardware, especially

fasteners used as connections to ground planes on PCBs

Power source

• Faulty wiring, especially AC outlet

• Circuit not dedicated to system

NOTE:

Power source problems can cause static discharge,

resetting problems, and noise.

Keyboard

• Cuts or cracks in keyboard membrane

• Illegible labels

LCD display filter

Scratches, cracks, or an opaque display filter (transparent

component of keyboard bezel) that impair viewing

Battery pack

• Cracked, swollen, or leaky battery pack enclosure

• Debris on battery pack electrical contacts

SD card

• Cracked SD card

• Broken gold contacts

• Dirt, scratches, or debris on contacts

Event Logging

Event logging is a way to track system errors, warnings and informational messages.

Setting Up Event Logging

You can set up the system to create an

Event Log

in XML format. To configure the

device for the level of severity of messages written to the

Event Log

, use the following

steps:

1.

Power on the system by pressing the

Power

button.

2.

On the

Main Menu

, press

F5

(

System Configuration

).

3.

Press

F6

(

More

) >

F6

(

More

) >

F5

(

Service Setup

).

A window opens prompting you to enter the

Service password

.

2028451-183E

MAC™ 1600

31

Summary of Contents for MAC 1600

Page 18: ...Introduction 18 MAC 1600 2028451 183E...

Page 26: ...Equipment Overview Block Diagram 26 MAC 1600 2028451 183E...

Page 28: ...Equipment Overview 28 MAC 1600 2028451 183E...

Page 108: ...Maintenance 108 MAC 1600 2028451 183E...

Page 111: ...Parts Lists 2028451 183E MAC 1600 111...

Page 112: ...Parts Lists 112 MAC 1600 2028451 183E...

Page 113: ...Parts Lists 2028451 183E MAC 1600 113...

Page 128: ...Parts Lists 128 MAC 1600 2028451 183E...

Page 140: ...Electromagnetic Compatibility 140 MAC 1600 2028451 183E...

Page 145: ......