APPLICATION EXAMPLE

D485 MODBUS TO DEVICENET CONVERTER – USER GUIDE

9–7

STEP 2: SELECTING THE

SUB-NETWORK

PROPERTIES

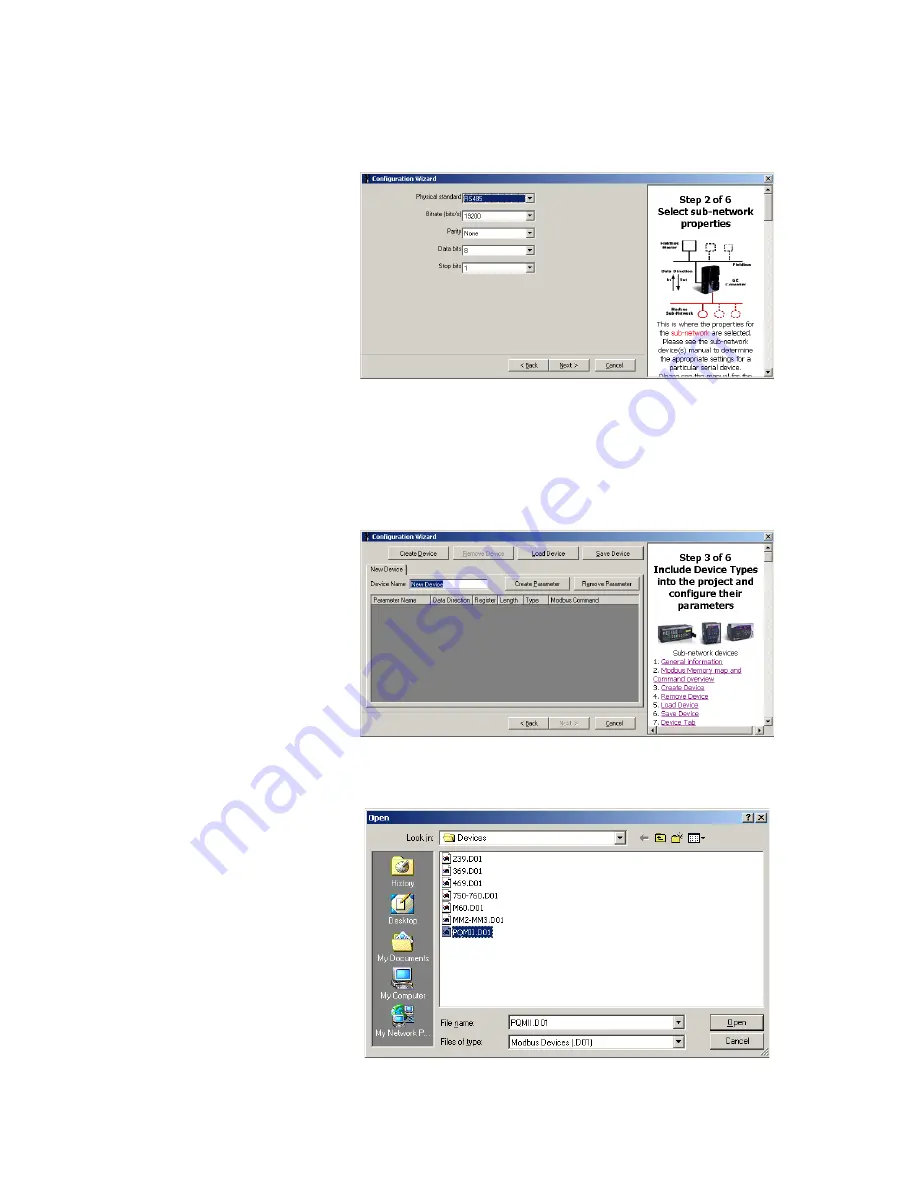

The second step in the configuration wizard is selecting the sub-network properties.

1.

Set the Modbus network properties as follows: baud rate to 19200, with 8 data bits, no

parity, RS485 physical standard, and 1 stop bit.

Figure 9-6: Modbus network properties

2.

Click

Next

to proceed to step 3 of the configuration wizard.

STEP 3: INCLUDE DEVICE

TYPES

The third step in the configuration wizard is to include device types. The PQMII and MM2

devices are added in this step.

1.

The configuration wizard gives the option to create a configuration for a new device

or to load a configuration of saved device.

Figure 9-7: Device types

2.

Configuration files for MM2 and PQMII are supplied with the EnerVista P485/D485

Setup software. Click the

Load Device

button to see the available configuration files.

Figure 9-8: Available Modbus devices

Summary of Contents for D485

Page 32: ...3 14 D485 MODBUS TO DEVICENET CONVERTER USER GUIDE DATA EXCHANGE ...

Page 46: ...4 14 D485 MODBUS TO DEVICENET CONVERTER USER GUIDE SOFTWARE OVERVIEW ...

Page 52: ...5 6 D485 MODBUS TO DEVICENET CONVERTER USER GUIDE COMMUNICATION MODEL ...

Page 92: ...9 20 D485 MODBUS TO DEVICENET CONVERTER USER GUIDE APPLICATION EXAMPLE ...

Page 94: ...10 2 D485 MODBUS TO DEVICENET CONVERTER USER GUIDE MISCELLANEOUS ...