30 - 50 mm

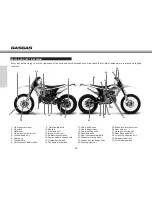

Drive Chain Slack Inspection

The space between the chain and the swingarm at the same height

of the chain slider should be 30-50 mm. Rotate the rear wheel to

find the place where the chain is tighter. Adjust the drive chain if it

has too much or too little slack.

In addition to checking the slack, rotate the rear wheel to inspect for

damaged rollers, loose pin and links, unevenly or excessively worn

teet, and damaged teeth.

-

25-

- Remove the retaining screws of the right side number-posting cover .

Changing the silencer packing

- Remove all cover rivets with a drill.

- Remove the inside core of the muffler.

- Replace the muffler fibre by wraping it around the inner tube.

- Reinstall the assembly.

-(A). Screw.

-(B). Silencer.

-(C). Rivet.

DRIVE CHAIN GUIDE

The drive chain must be checked, adjusted, and lubricated in

accordance with the Maintenance Schedule. If the chain is worn or

adjusted incorrectly (either too loose or too tight) the chain could

become loose or break. Replace the chain, if necessary.

WARNING

A chain that breaks or becomes loose could snag on the engine or

on the rear wheel, severely damaging the motorcycle and causing

it to go out of control