© All rights reserved - Galmet Sp. z o.o. Sp. K.

Installation and Operating Manual / Warranty Card - SGW(S), SGW(S)B, SG(S)

3

1. Operation and service

1.1. Heater characteristics

Hot tap water heater is designed to heat water and store it in a heated state. It can be used to meet the needs of households in establishments catering,

public welfare establishments, etc. The heater is designed to work only in horizontal or vertical position, depending on the type. It can be connected to the

water supply at a pressure not exceeding 0,6 MPa - about 6 bar (in the case of tanks with capacity from 100 liters to 140 liters) and 1 MPa - about 10 bar (in

the case of tanks with capacity from 200 liters to 1500 liters). The water can be heated by the spiral wound heat exchanger which (i.e. high surface area coil)

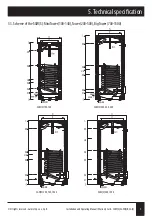

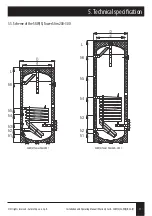

connected to the central heating boiler. The basic model is a hot tap water heater with one coil (pt. 5.3; 5.5; 5.7). We offer water heaters with two spiral coils

(bivalent): one coil for the CH system and the other for the solar heating system (pt. 5.10; 5.12; 5.14). Lower coil cooperates with a solar collector, and the

top coil with the CH boiler or a heat pump. We offer hot tap water reservoirs (pt. 5.16; 5.18) and horizontal water heaters (pt. 5.18). Anticorrosion protection

is provided by a ceramic enamel burned at 850°C. Moreover, large magnesium anode acts as an extra protection. Heaters are insulated with ecological

polyurethane or polystyrene foam, which reduces heat loss to an absolute minimum.

1.2. Description

The main part of the heater is a tank in which the water is heated. The tank is made of a steel sheet, which is coated on the inside with ceramic enamel.

Technological holes in the bottoms of the tank are closed with stoppers. The tank is equipped with two coil connections; the cold water outlet and inlet

connections are located next to each other on one side of the tank. In addition, there is also provided an opening for connecting the circulation and the

sensor cover - to which the sensor can be connected with the boiler thermostat (tube 3/8”). The standing heaters 100 to 140 l in the top of the bottom

anode is located, which is placed on the stopper 5/4”. Tanks are from 200 to 1500 l, there are two magnesium anodes: one is arranged in the opening of

the manhole M8 screw and the other is at the top of the bottom on the heels of 5/4” (200 - 500 l), 2” (700 - 1500 l). Heaters are equipped with additional

connections (3/4 „ capacity. 100-140 l and 1” capacity. 200 -1500 l) where you can install the drain valve .

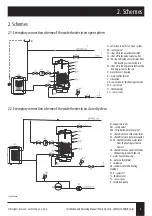

In the SGW(S)B 200 , SGW(S) SLIM 200-300 , SGW(S)B 200-300 SLIM and SGW(S) horizontal 140-300 water heaters it is recommended to install a tee on

the cold water inlet as well as a the drain valve in order to properly drain the tank (pt. 2.3).

1.3. Venting the coil in horizontal heaters

For easier (simpler) venting of the spiral coil it is necessary to:

- put the tank in a vertical position (on the lid),

- close the return from the coil (f.ex. by using a ball valve),

- pour water or glycol solution into the coil (depending on the type of installation),

- close the coil's supply connection (f.ex. by using a ball valve),

- mount the tank on the frame (not included),

- connect the tank to the installation.

1.4. Installation

Connection of the water heater should be done by the installer with the appropriate permissions. The installation must be confirmed in the warranty card.

The heater must be installed in vertical or horizontal position depending on the type of the tank.

The heater should be connected directly to the water supply (with the possibility of disconnection, f.ex. in the case of maintenance) at a pressure not

exceeding 0,6 MPa (tanks with the capacity between 100 and 140 l) and 1,0 MPa - about 10 bar (tanks with the capacity between 200 and 1500 l) while the

minimum pressure shall be not less than 0,1 MPa (approx. 1 bar). If the water pressure in the mains supply exceeds 0,6 MPa tanks with the capacity between

100 and 140 l) and 1,0 MPa - about 10 bar (tanks with the capacity between 200 and 1500 l) the pressure must be reduced by the use of a pressure regulator.

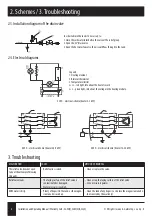

Safety valve must be installed on the cold water supply pipe (f. ex. ZB4/ZB8 valves from FACH Cieszyn or ZB7/ZB9 valves from Orkla Spain) according to the

direction of the arrow located on the tank. The safety valve can reduce pressure without the water overflowing to the supply installation (it opens the flow

of the differential pressure in the heater and installation amounting to 0,07 0,03 MPa, which is why cold water supply pipe must withstand a temperature of

90°C up to 5 meters from the safety valve (because of the possibility of the flow of hot water from the tank into the installation). An outflow opening in the

safety valve must be constantly connected to the open atmosphere. Before using the installation it is necessary to check all of the connections for leakage,

1. Operation and service