37/86

Gala Gar, S.L. c/ Jaime Ferrán, 19 (Políg. Cogullada) | Tel.: (+34) 976 47 34 10 - 50014 ZARAGOZA |

SMART 210 TIG PULSE

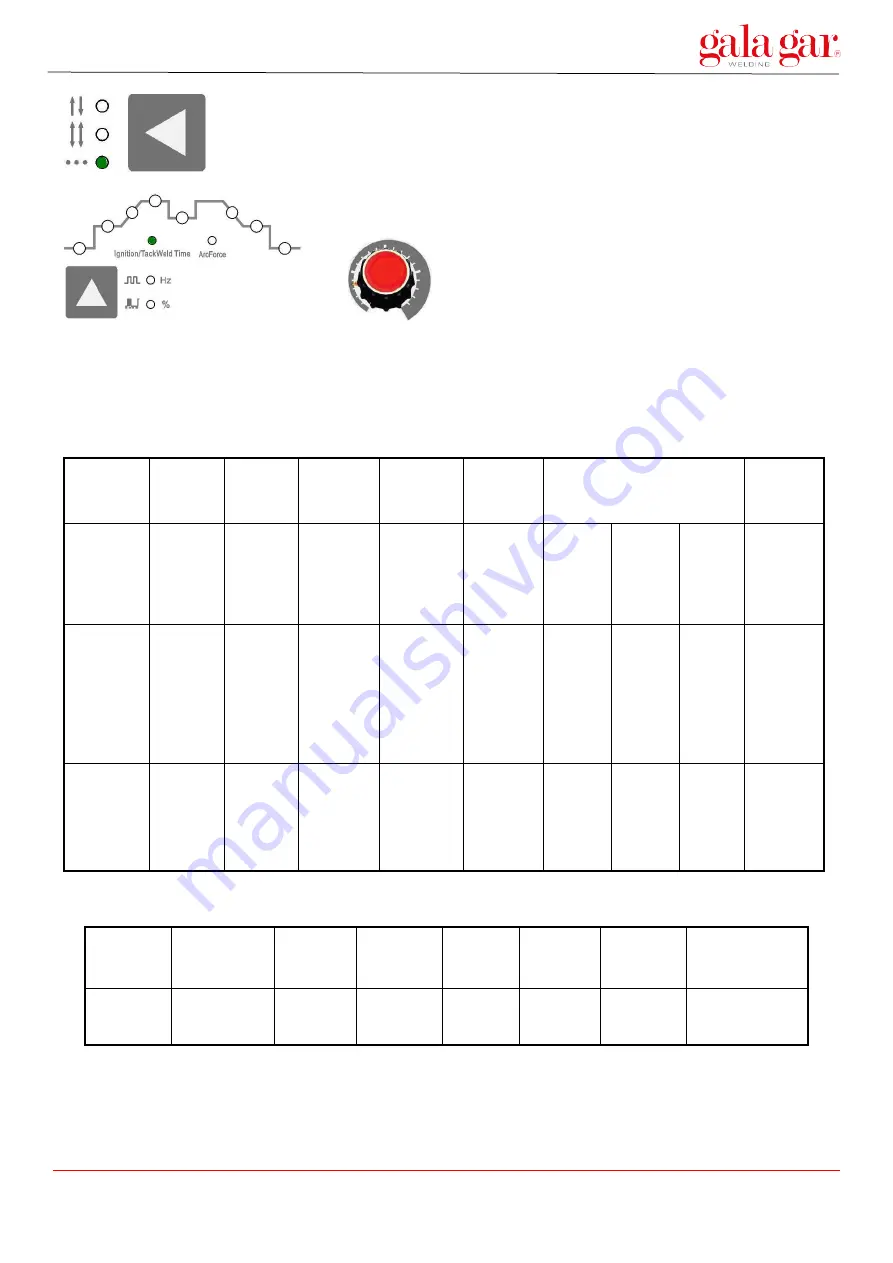

Select spot welding mode by pressing the operation mode selecting key.

Select spot welding time setting function by pressing the welding parameter selecting key, and set the spot welding

time. Besides, the spot welding time setting can be carried out during welding. Operation steps in spot welding: Press

the torch trigger, gas valve opens, and HF arc ignition starts; Keep the torch 2~4mm away from the workpiece to

ignite the arc, HF stops, and current turns to the preset value; Welding begins, and it ends when the spot welding

time is up. There is no current upslope and downslope in spot welding mode.

Parameters for TIG welding on titanium and its alloy (for reference only)

Plate

thickness

(mm)

Groove

type

Welding

layers

Electrode

diameter

(mm)

Wire

diameter

(mm)

Welding

current

(A)

Gas flow (L/min)

Nozzle

diameter

(mm)

0.5

1.0

1.5

2.0

2.5

Square

groove

1

1

1

1

1

1.5

2.0

2.0

2.0

~

3.0

2.0

~

3.0

1.0

1.0

~

2.0

1.0

~

2.0

1.0

~

2.0

2.0

30

~

50

40

~

60

60

~

80

80

~

110

110

~

120

8

~

10

8

~

10

10

~

12

12

~

14

12

~

14

6

~

8

6

~

8

8

~

10

10

~

12

10

~

12

14

~

16

14

~

16

14

~

16

16

~

20

16

~

20

10

10

10

~

12

12

~

14

12

~

14

3.0

4.0

5.0

6.0

7.0

8.0

Single V

groove

with root

face

1

~

2

2

2

~

3

2

~

3

2

~

3

3

~

4

3.0

3.0

~

4.0

4.0

4.0

4.0

4.0

2.0

~

3.0

2.0

~

3.0

3.0

3.0

~

4.0

3.0

~

4.0

3.0

~

4.0

120

~

140

130

~

150

130

~

150

140

~

180

140

~

180

140

~

180

12

~

14

14

~

16

14

~

16

14

~

16

14

~

16

14

~

16

10

~

12

12

~

14

12

~

14

12

~

14

12

~

14

12

~

14

16

~

20

20

~

25

20

~

25

25

~

28

25

~

28

25

~

28

14

~

18

18

~

20

18

~

20

18

~

20

20

~

22

20

~

22

10

20

22

25

30

Double V

groove

with root

face

4

~

6

12

12

15

~

16

17

~

18

4.0

4.0

4.0

4.0

4.0

3.0

~

4.0

4.0

4.0

~

5.0

3.0

~

4.0

3.0

~

4.0

160

~

200

200

~

240

230

~

250

200

~

220

200

~

220

14

~

16

12

~

14

15

~

18

16

~

18

16

~

18

12

~

14

10

~

12

18

~

20

20

~

26

20

~

26

25

~

28

20

18

~

20

26

~

30

26

~

30

20

~

22

18

20

22

22

Parameters for TIG welding on titanium and its alloy (for reference only)

Plate

Thickness

(mm)

Welding joint

Electrode

diameter

(mm)

Wire

diameter

(mm)

Current

type

Welding

current

(A)

Gas flow

(L/min)

Welding speed

(cm/min)

1.0

1.2

1.5

Butt Joint

2

2

2

1.6

1.6

1.6

DCEN

7

~

28

15

5

~

19

3

~

4

3

~

4

3

~

4

12

~

47

25

8

~

32