34/86

Gala Gar, S.L. c/ Jaime Ferrán, 19 (Políg. Cogullada) | Tel.: (+34) 976 47 34 10 - 50014 ZARAGOZA |

SMART 210 TIG PULSE

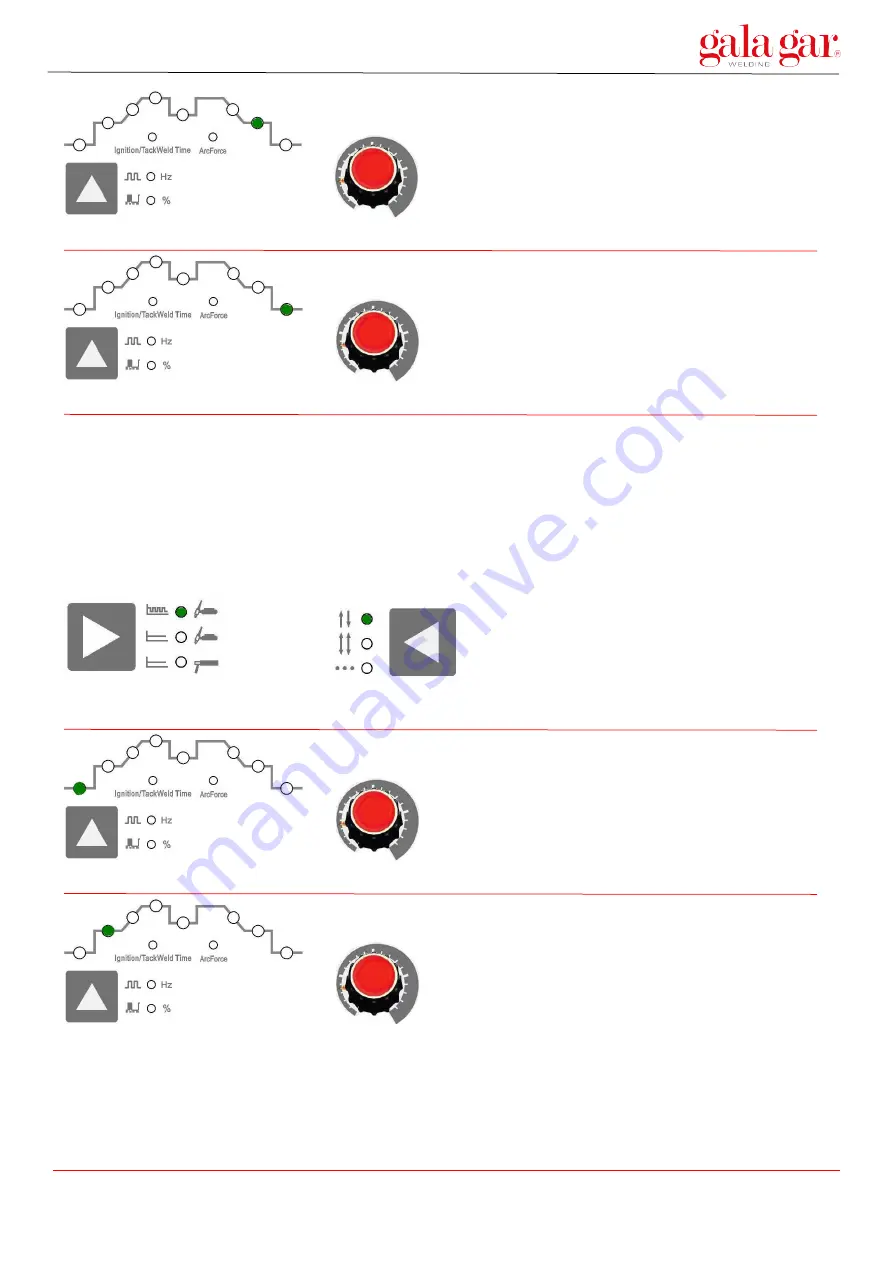

Select pilot arc current setting function by pressing the welding parameter selecting key, and set the pilot arc current.

Select post-flow time setting function by pressing the welding parameter selecting key, and set the post-flow time.

After the parameters are set appropriately, open the gas valve of the cylinder, and adjust the gas regulator to the

desired value.

Press the torch trigger, the solenoid valve works. There is gas output firstly, and then HF output.

Keep the torch 2~4mm away from the workpiece, and then press the torch trigger. After arc is ignited, the HF

discharge rustling disappears, the current rises up to the preset value, and welding can be carried out. After

releasing the torch trigger, the current begin to decrease automatically to the pilot arc value. Then, arc stops with gas

keeping flowing for the post-flow time, and welding ends.

Pulsed TIG:

Select pulsed TIG mode by pressing the welding mode selecting key, and select 2T mode by pressing the operation

mode selecting key.

Select pre-flow time setting function by pressing the welding parameter selecting key, and set the pre-flow time.

Select initial current setting function by pressing the welding parameter selecting key, and set the initial current.