88

13. Troubleshooting

13.1 Common Problems

The following guide lists the most common problems that may be encountered when operating

this bar code printer. If the printer still does not function after all suggested solutions have been

invoked, please contact the Customer Service Department of your purchased reseller or

distributor for assistance.

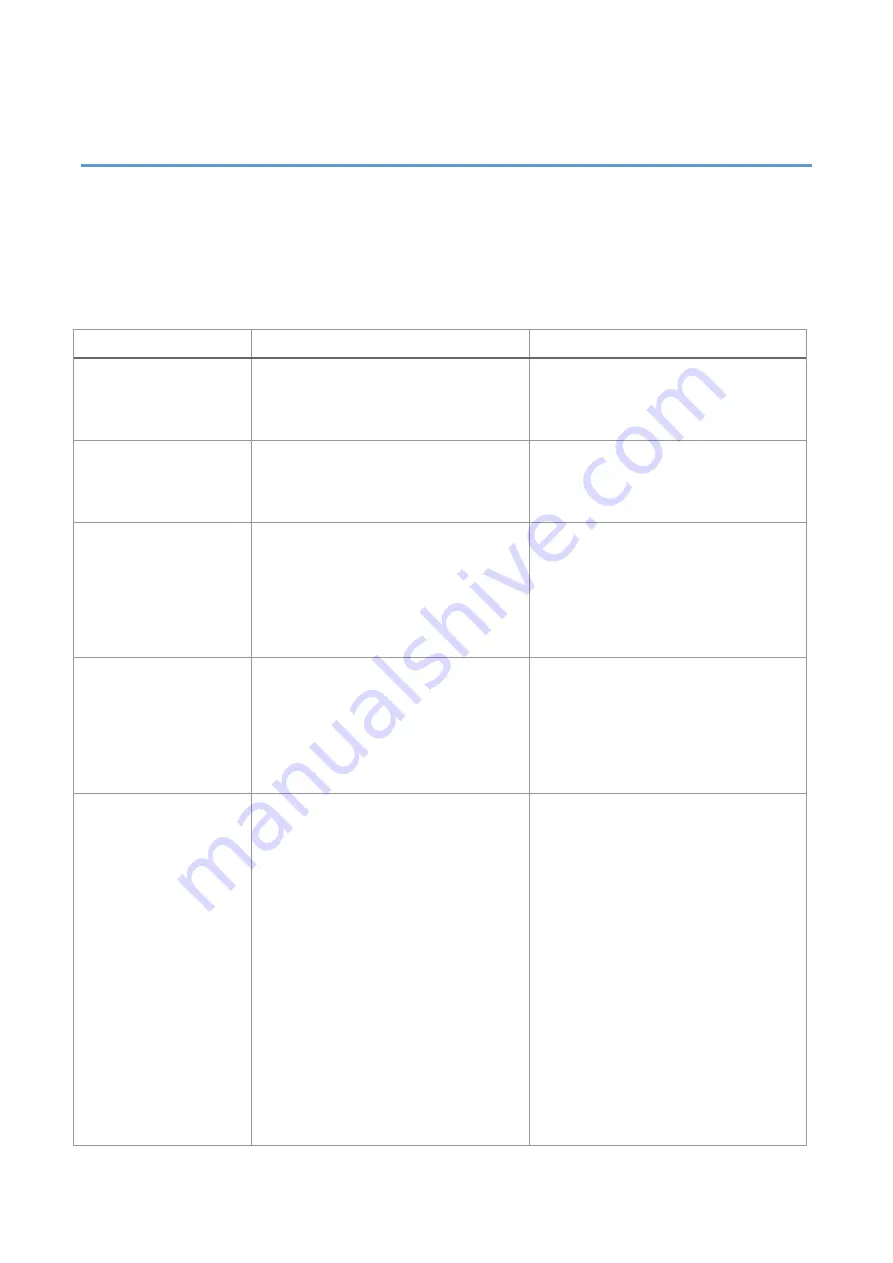

Problem

Possible Cause

Recovery Procedure

Power indicator does

not illuminate.

The power cord is not properly

connected.

Plug the power cord in printer and

outlet.

Switch the printer on.

Out of ribbon

Out of ribbon.

The ribbon installation path is

incorrect.

Install new ribbon.

Follow the steps for installing the

ribbon to reinstall.

Out of paper

Out of paper.

The paper installation path is

incorrect.

Gap / black mark sensor detection

is incorrect.

Install new paper.

Follow the steps for installing the

paper to reinstall.

Recalibrate the label sensor.

Paper jam

Gap / black mark sensor detection

is incorrect.

The label size is set incorrectly.

Label may be blocked inside the

printer.

Recalibrate the label sensor.

Set the correct label size.

Cleaning the inside of the printer.

Unable to print

Cable is not well connected to

serial or USB interface or parallel

port.

Re-connect cable to interface.

Change a new cable.

Ribbon and media are not

compatible.

Verify the ribbon-inked side.

Reload the ribbon again.

Clean the print head.

The print density setting is

incorrect.

Print head’s harness connector is

not well connected with printhead.

Turn off the printer and plug the

connector again.