RX200 S3

Operating Manual

13

Introduction

Technical data

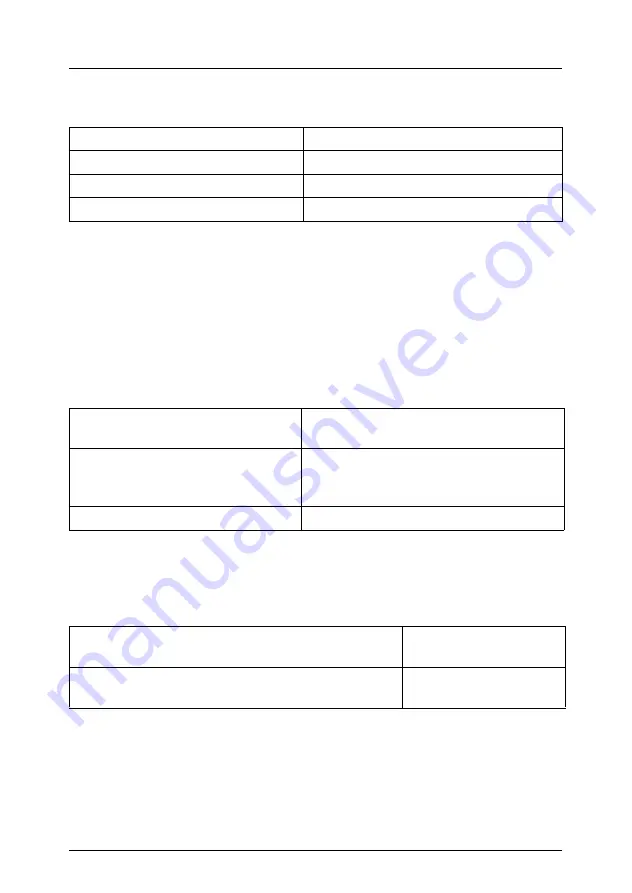

Mechanical values

Weight

Approx. 17 - 18 kg (depending on configuration)

Ventilation clearance

At least 200 mm on the front and on the rear side

Environmental conditions

Condensation must be avoided during operation.

Noise level

Width (without front panel)

430 mm

Installation depth

729 mm

Total depth (with front panel)

773 mm

Height

43 mm or 1 HU

Environment class 3K2

Environment class 2K2

EN 60721 Part 3-3

EN 60721 Part 3-2

Temperature:

Operation (3K2)

Transport (2K2)

5 °C ... 35 °C

- 25 °C ... 60 °C

Humidity

10% ... 85%

Sound power level L

WAd

(ISO 9296)

≤

6.7 B (standby)

≤

7.5 B (operating)

Sound pressure level at bystander position

L

pAm

(ISO 9296)

≤

50 dB (A) (standby)

≤

58 dB (A) (operating)