U41271-J-Z156-2-76

37

Installation

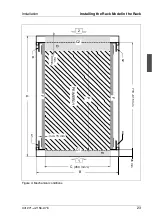

Installing the Rack Model in the Rack

Ê

Mount the necessary manufacturer original parts (like support bracket or

cable management).

I

Sometimes a number of parts of the delivered mounting kit cannot be

used because original parts of the 3rd-Party Rack are to be used.

Ê

Mount the supplied four assembly brackets on the telescopic rails as

described in section “Mounting in the PRIMECENTER Rack” on page 24.

Ê

Mount the assembled telescopic rails with the brackets in the 3rd-Party Rack

as described in section “Mounting in the PRIMECENTER Rack” on page 24.

Ê

Mount the server (see section “Installing the Server” on page 38).

Ê

Route the cables as described in the original manual of the Rack.

Ê

Secure the server on the front panel using four knurled screws (see figure 18

on page 39).